Typically, a 3-phase motor is capable of running at a high efficiency and power factor. These motors are commonly found in industrial machinery and automobile propulsion systems. They are also used for hydraulic pumps and compressors. In addition, three phase motors are used in large air conditioning equipment. They are durable and require little maintenance.

Three phase motors are designed to work with three windings and a series of electromagnets. The field created by these currents is rotated by the rotor, and the net torque is applied to the motor shaft. Because of the nature of these motors, there is a measurable amount of electrical energy in the field, which is what the multimeter is able to detect. This is a simple way of checking the power supply and the overall health of a motor. If the readings are outside of the range of what the motor is supposed to perform, this may indicate a problem.

The three phases in a three-phase system carry alternating currents of the same frequency. The power delivered is constant over the cycles of the current. The instantaneous peak values are at different times during the cycle. The three-phase system is an effective way to provide constant power transfer.

When a three-phase motor starts up, a high voltage line jolts the motor into a starting position. The magnetic field then aligns to the rotor, which causes the rotor to start in a counterclockwise direction. Depending on the speed of the rotor and the motion of the magnet, the presence of an EMF will vary.

A three-phase induction motor is a highly reliable and low-maintenance machine. The rotor and the stator are connected to the motor shaft through bearings and end caps. A fan is located in the enclosure to draw ambient air from the outside of the enclosure and dissipate heat generated in the coils.

A three-phase asynchronous motor, on the other hand, has no direct connection to the rotor. The motor works by Faraday's law of induction. The electromagnets in the rotor field are aligned to the stator field to produce a revolving magnetic field. A capacitor is used to reverse the rotation, which is accomplished by connecting it to the T2 terminal.

One of the most important aspects of a three-phase induction motor is the fact that it requires very little maintenance. The windings on the motor must be the same, and the resistance between the windings should be a minimum of 1,5 Mohm.

A three-phase motor should be able to deliver double the hp of a single-phase motor. This will give you more consistent current output and lower your operating costs. Depending on the power required, a three-phase motor can be a valuable investment.

In order to run an efficient three-phase motor, you will need a high angular velocity and a lot of power. The typical three-phase motor is capable of delivering between 75% and 95% efficiency. It should also be able to generate a power factor of at least 0.80.

English

English عربى

عربى

Fire Pump and System

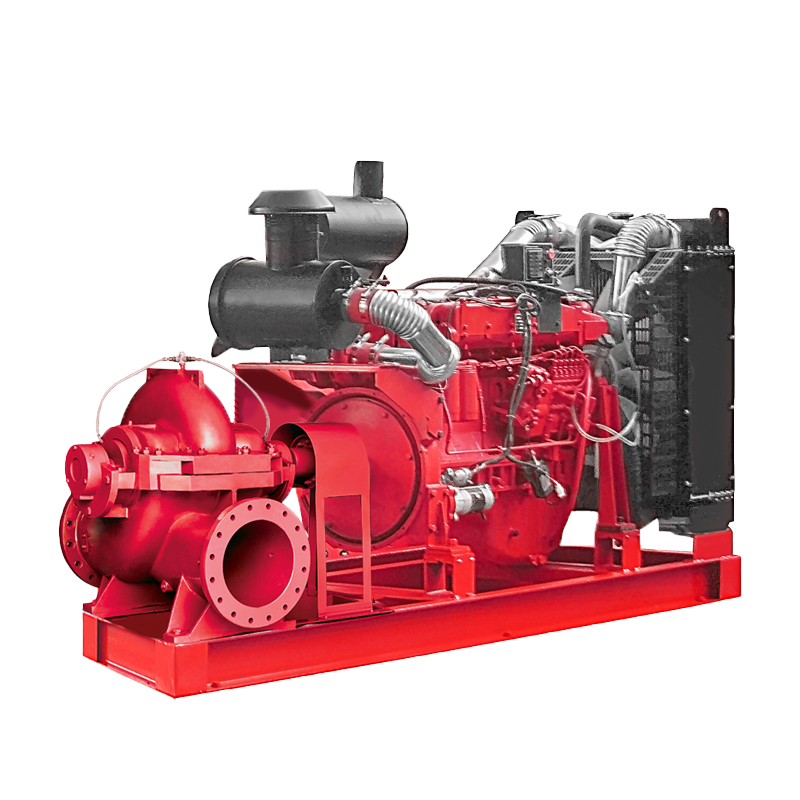

Fire Pump and System Split Case Pump

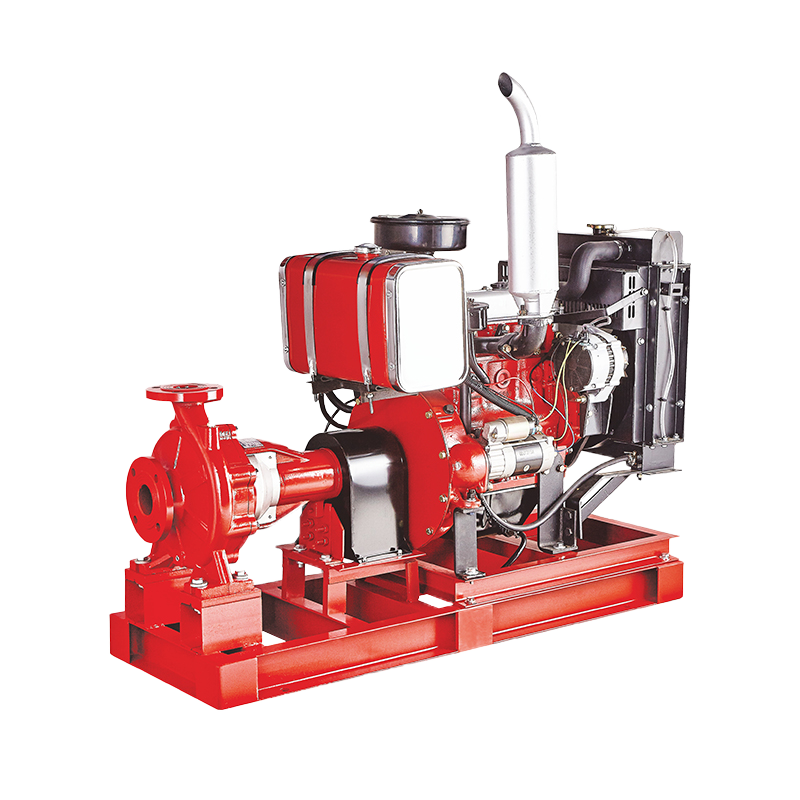

Split Case Pump Engine and Pump

Engine and Pump Long Shaft Pump

Long Shaft Pump Multistage pump

Multistage pump Water Supplier System

Water Supplier System Sewage Pump

Sewage Pump Industrial Pump

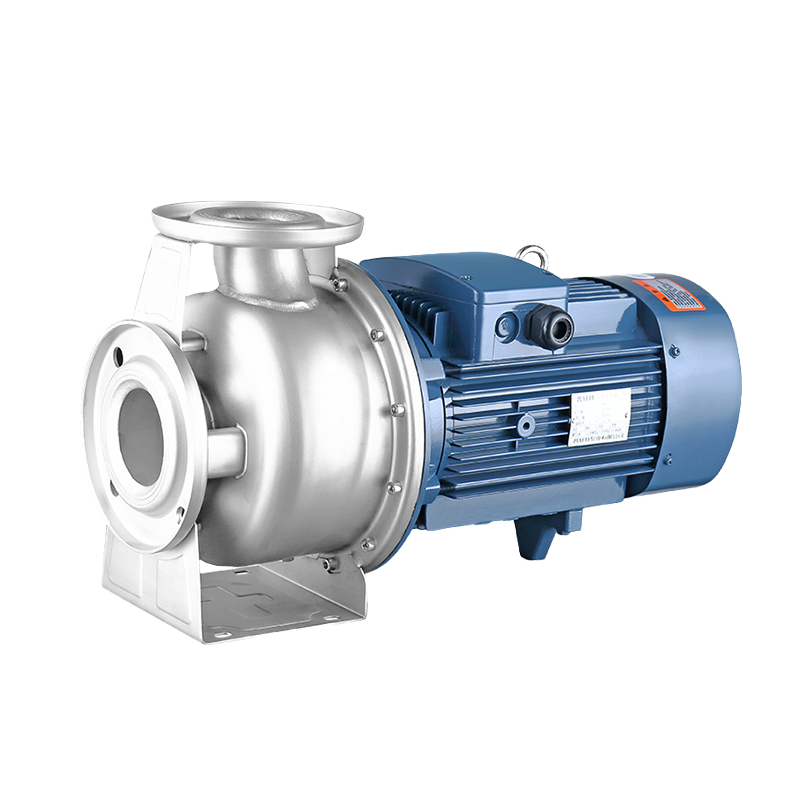

Industrial Pump Self-Priming Pump

Self-Priming Pump Inline Pump

Inline Pump Domestic Pump

Domestic Pump Electric Motor

Electric Motor Borehole Pump

Borehole Pump