A horizontal centrifugal pump is a type of centrifugal pump. Its efficiency is boosted by using diffusers to direct the flow. The diffusers help increase the pump's efficiency by allowing the pump's internal volume to expand gradually. Its low failure intervals make it a great choice for many applications. Here are some features to look for in a horizontal centrifugal pump.

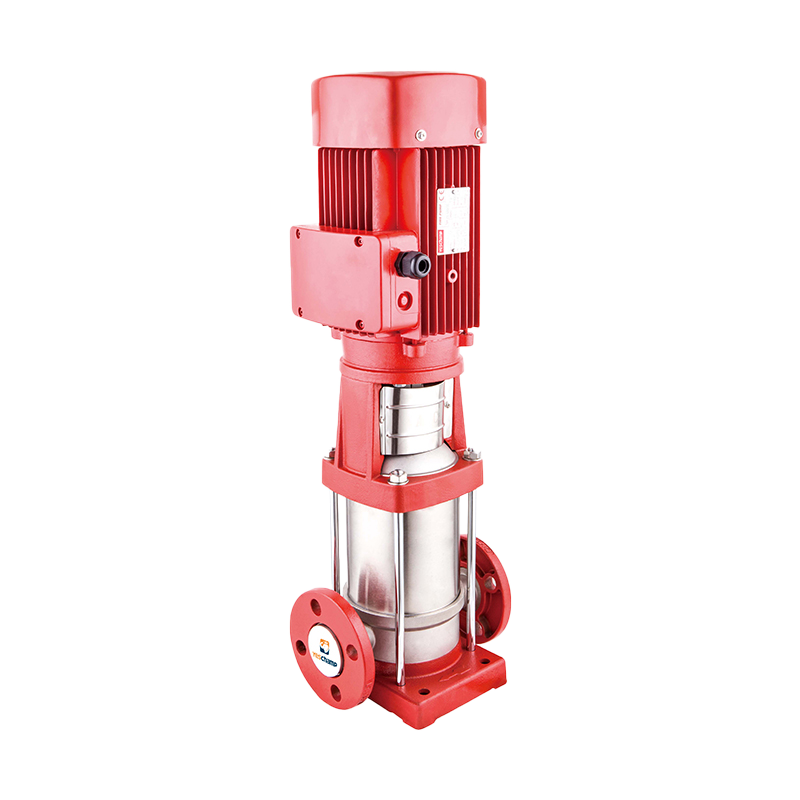

Multistage centrifugal pump

A Multistage horizontal centrifugal pump is an ideal choice for transferring fluids between points in a wide range of applications. The pump's segmented casing and modular interstage allow it to operate at higher temperatures and pressures. In addition to their superior quality, these pumps also offer subtle noiseless operation. Read on to learn more about this type of pump. Here are the top benefits of this type of pump.

The MIPA Series pumps are commonly used in energy-efficiency projects due to their high performance, low noise and high durability. Multistage pumps are easy to install and maintain and are suitable for use in a variety of applications, from domestic to industrial settings. These pumps are also suited for applications requiring corrosive media, hot water, and oil. If you're looking for a high-quality pump that won't break the bank, Multistage is a solid choice.

Vortex casing

A vortex casing is a type of casing that reduces pressure energy by creating a circular chamber. Fluid passes through the casing and eddies are minimized. It also decreases energy loss in a horizontal centrifugal pump. It is often found in pumping systems for liquids in the paper and pulp industry. Moreover, vortex casings are also beneficial in corrosive environments.

The power of a centrifugal pump is measured in horsepower. The power is proportional to the length of the pump and includes the head loss caused by pipe bends. Power is typically measured in horsepower or kilowatts, which is hp / kilowatts. The total power is then multiplied by the pump's running time to determine its energy usage.

High efficiency

The most common type of horizontal centrifugal pump is the high efficiency model. Its efficiency can range from 80 to 90 percent depending on the design. The design process starts with determining the pump's specific speed. Then, it works backwards by dividing the speed by two to get the GPM. This way, the efficiency of the pump can be determined in advance. Once you have the pump's NPSH and BHP, you can calculate how much water it will pump.

In terms of installation, horizontal pumps are usually easier to install and less expensive to maintain. Self-priming horizontal centrifugal pumps are special-purpose pumps used for different applications, such as irrigation systems. They are also more accessible for maintenance. In some cases, the high-efficiency vertical centrifugal pump may be installed in a floating system where the impeller remains under water. Self-priming horizontal centrifugal pumps are particularly desirable if you experience frequent power outages or prefer off-peak electrical prices.

Low intervals of failure

When a pump begins to have recurring problems, it is important to know why the condition first arose. If it suddenly started failing, it probably isn't the result of normal wear and tear and likely represents some sort of action that the pump was not designed to handle. Therefore, troubleshooting should focus on identifying the root cause of the failure and how to fix it. Below are three tips to help you identify a failing pump and determine what needs to be done.

While the horizontal centrifugal pump is fluid-tight and efficient, there are three major causes of failure. These are insufficient fluid in the casing, too high a total head, and too much suction lift. In order to fix the latter problem, the pump should be shorted or the suction lift reduced. If the total head or suction lift is too high, the pump's gasket may need to be replaced.

Cost

The basic concept behind a horizontal centrifugal pump is that fluid flows in one direction and leaves at the other. This pump is a simple pump with two main parts - an impeller and a casing. Fluid enters the casing through the impeller and falls onto its blades. As the impeller rotates, it gains pressure and velocity, transmitting the fluid from a low point to a high point. The pump can have one or more impellers to accommodate high-pressure and temperature fluids.

One type of horizontal centrifugal pump is the single-stage type, which has a single stage and is available in a range of power ratings. These pumps are relatively inexpensive and have simple structures. They can be used for pressurized water supply in high-rise buildings. Single-stage models are available with a flow rate of up to 65 m3/h and a head of up to 127m. Single-stage models are ideal for circulation of water in HVAC and refrigeration systems.

English

English عربى

عربى

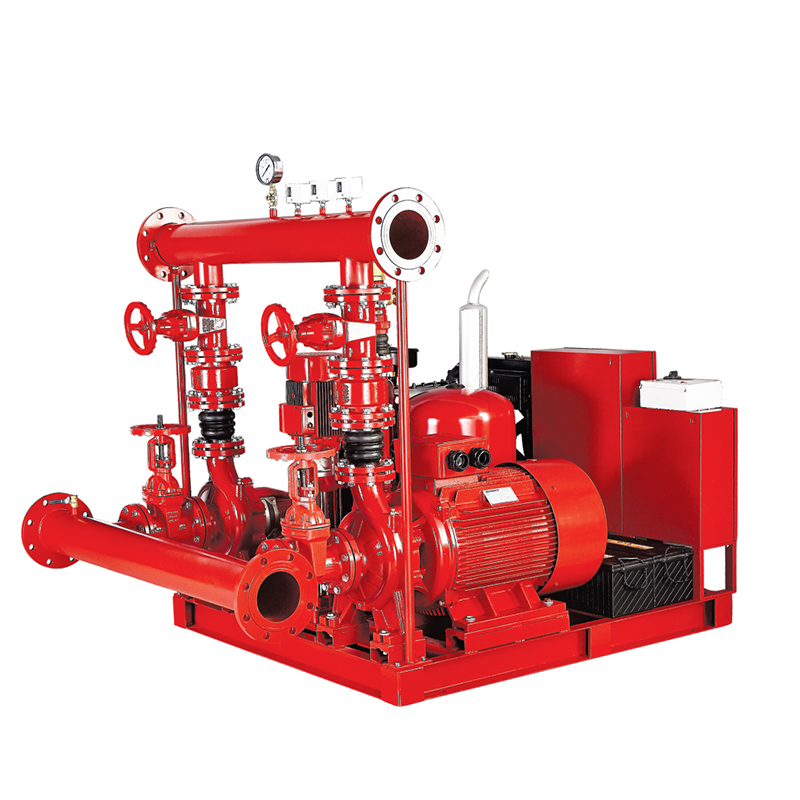

Fire Pump and System

Fire Pump and System Split Case Pump

Split Case Pump Engine and Pump

Engine and Pump Long Shaft Pump

Long Shaft Pump Multistage pump

Multistage pump Water Supplier System

Water Supplier System Sewage Pump

Sewage Pump Industrial Pump

Industrial Pump Self-Priming Pump

Self-Priming Pump Inline Pump

Inline Pump Domestic Pump

Domestic Pump Electric Motor

Electric Motor Borehole Pump

Borehole Pump