Vertical Multistage Pump: High-Performance Solution for Fluid Handling

A vertical multistage pump is a highly efficient and compact pump designed for applications requiring high-pressure fluid transfer. With its vertical design and multiple impellers, this pump is ideal for industries and systems that need consistent water flow and space-saving solutions. From high-rise buildings to industrial processes, vertical multistage pumps are the go-to choice for reliable performance and energy efficiency.

What Is a Vertical Multistage Pump?

A vertical multistage pump is a centrifugal pump with multiple impellers mounted vertically in a series. Each stage consists of an impeller and a diffuser, working together to increase the pressure of the fluid as it moves through the pump. The vertical design allows the pump to handle high pressures without taking up much horizontal space, making it choice for installations with limited floor area.

These pumps are widely used for transporting clean water or other low-viscosity fluids, making them versatile for a range of applications.

How Does a Vertical Multistage Pump Work?

The working principle of a vertical multistage pump involves:

Fluid Entry

The liquid enters the pump through the suction port at the bottom.

Pressure Increase

As the fluid passes through each stage, the impeller adds kinetic energy, which is converted into pressure by the diffuser.

Continuous Compression

The multiple stages build up pressure progressively, providing the high head required for demanding applications.

Fluid Discharge

The pressurized fluid exits through the discharge port at the top of the pump.

This multi-stage process ensures efficient and reliable operation for high-pressure systems.

Benefits of Vertical Multistage Pumps

Choosing a vertical multistage pump offers numerous advantages:

1. Space-Saving Design

The vertical configuration minimizes horizontal footprint, making it ideal for tight spaces.

2. High Efficiency

Multiple impellers ensure efficient energy use with minimal wastage.

3. Consistent Performance

Delivers steady flow and pressure, even in demanding applications.

4. Versatility

Suitable for a wide range of fluids and operating conditions.

5. Long Service Life

Robust materials and construction ensure durability and reliability.

6. Reduced Operating Costs

Energy-efficient design helps lower electricity bills over time.

How to Choose the Right Vertical Multistage Pump

1. Flow Rate and Pressure Requirements

Determine the required flow rate (in gallons per minute or liters per second) and pressure (in PSI or bar).

2. Fluid Type

Ensure the pump materials are compatible with the fluid's properties, such as temperature, viscosity, and chemical composition.

3. Pump Materials

For corrosive or abrasive fluids, choose pumps with stainless steel or chemical-resistant components.

4. Energy Efficiency

Opt for energy-efficient models to reduce operational costs.

5. Installation Space

Verify the vertical pump design fits the available area.

6. Reputable Manufacturer

Choose a trusted brand that offers warranties, spare parts, and customer support.

7. Maintenance Requirements

Look for pumps with easy-to-maintain designs to reduce downtime.

A vertical multistage pump is a versatile, efficient, and space-saving solution for high-pressure fluid transfer. With its ability to deliver consistent performance across a range of applications, including water supply, HVAC systems, and industrial processes, it has become a preferred choice for businesses and industries worldwide.

When selecting a vertical multistage pump, consider factors such as flow rate, pressure, fluid type, and energy efficiency to ensure performance. Proper maintenance will further enhance its reliability and extend its service life.

English

English عربى

عربى

Fire Pump and System

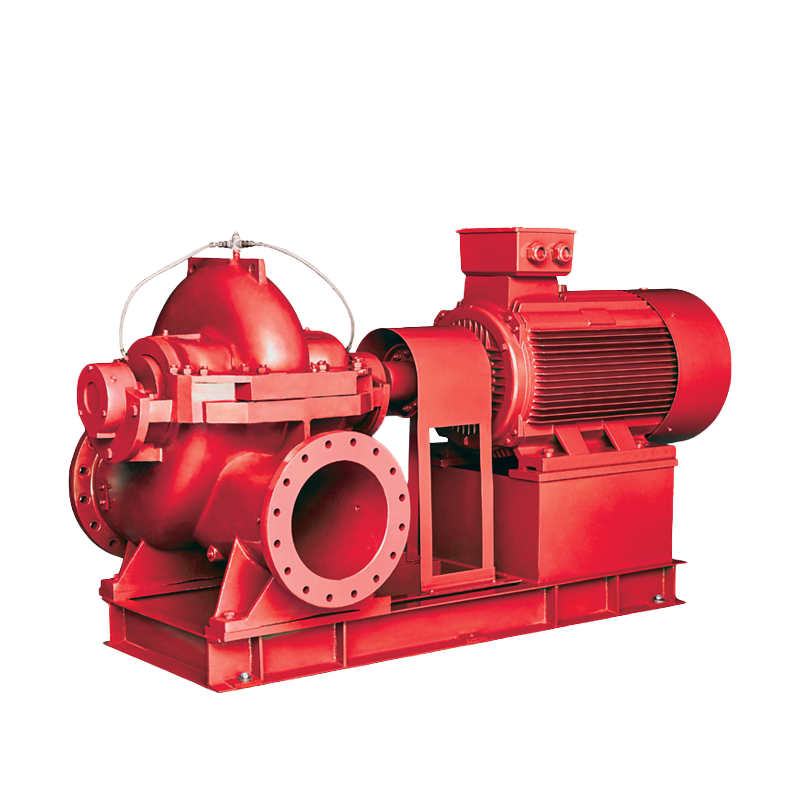

Fire Pump and System Split Case Pump

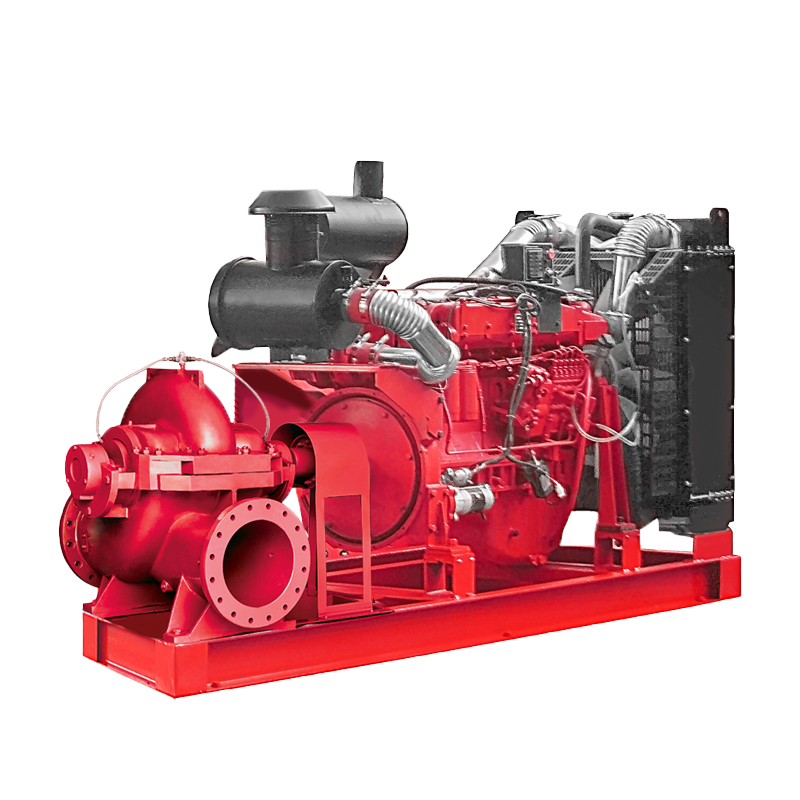

Split Case Pump Engine and Pump

Engine and Pump Long Shaft Pump

Long Shaft Pump Multistage pump

Multistage pump Water Supplier System

Water Supplier System Sewage Pump

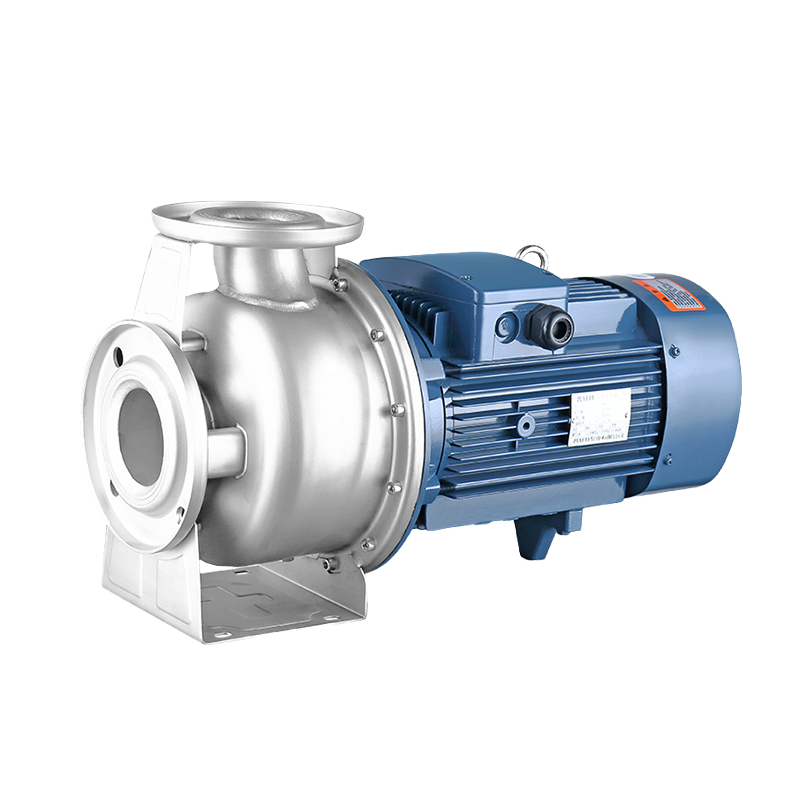

Sewage Pump Industrial Pump

Industrial Pump Self-Priming Pump

Self-Priming Pump Inline Pump

Inline Pump Domestic Pump

Domestic Pump Electric Motor

Electric Motor Borehole Pump

Borehole Pump