Suction Fire Pump Sets

If you are looking for Suction Fire Pump Sets, you've come to the right place. Learn about NFPA 20 standards, types of pumps, and how to install and maintain them properly. If you're still confused, read on. Here's some basic information to help you choose the best set for your needs. Also, be sure to check UL certification for fire safety and quality. The UL seal of approval guarantees that your product meets the highest standards for safety and performance.

NFPA 20

When it comes to water flow tests, the requirements of NFPA 20, or National Fire Protection Association, for suction fire pump sets are fairly strict. In the first place, pumps must operate for at least one hour during the test, but in the 2013 edition, the NFPA added some advisory language to clarify how the test is performed. Additionally, pump discharge tests are not required to run for the entire one-hour duration, which allows for shorter flow tests. Pump discharge tests are important because the water flow test will help maintain proper operating temperatures and prevent pump equipment from overheating.

The second part of the test requirements focuses on packaged assemblies. A packaged fire pump assembly consists of all of the parts necessary to run the pump, including the driver, controller, and other accessories. The package must be shipped as a single unit to the installation site, and is required to include the pump, controller, and enclosure, among other parts. NFPA 20 has also expanded its requirements for packaged assemblies, including welder qualification in accordance with Section 9 of the ASME Boiler and Pressure Vessel Code and American Welding Society AWS D1.1.

Types of pumps

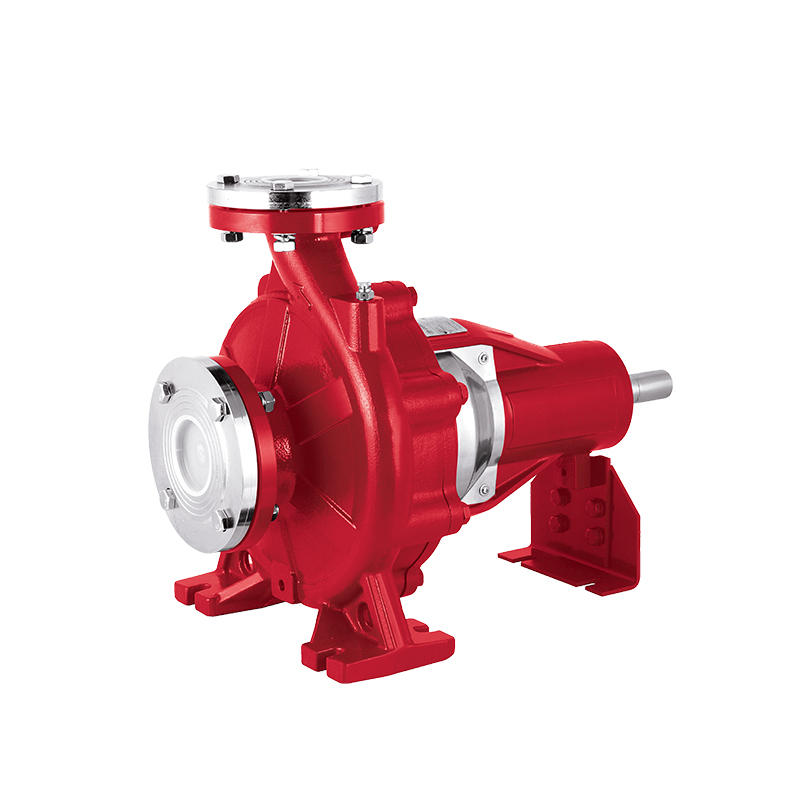

There are two main types of suction fire pump sets: centrifugal pumps and positive displacement pumps. Both types utilize centrifugal force to draw in water. Centrifugal pumps are usually the first choice for marine fires due to their affordability, ease of maintenance, and simplicity. However, centrifugal pumps must be primed before use. Because of this, they should be primed periodically. Positive displacement pumps, on the other hand, can discharge higher pressures of water and are capable of releasing mist.

Horizontal split case pumps feature a split design, allowing the casing cover to be removed and two bearings on the impeller. This design makes it possible to handle high pressures and large flows. They are commonly used for below-grade tanks, lakes, and underground wells. Moreover, the HSC design is durable and allows for large flows of water. Therefore, end suction pumps are best suited for industrial settings where water mist is a major issue.

Installation

The installation of suction fire pump sets is governed by regulations in San Francisco. Specifically, it is crucial to use approved backflow prevention assemblies and install them near the point of connection. These assemblies must be installed as close as possible to the fire pump, but must not exceed 25 feet away from the connection point. The suction piping must be installed with air pockets in mind, and an automatic release valve is not considered acceptable.

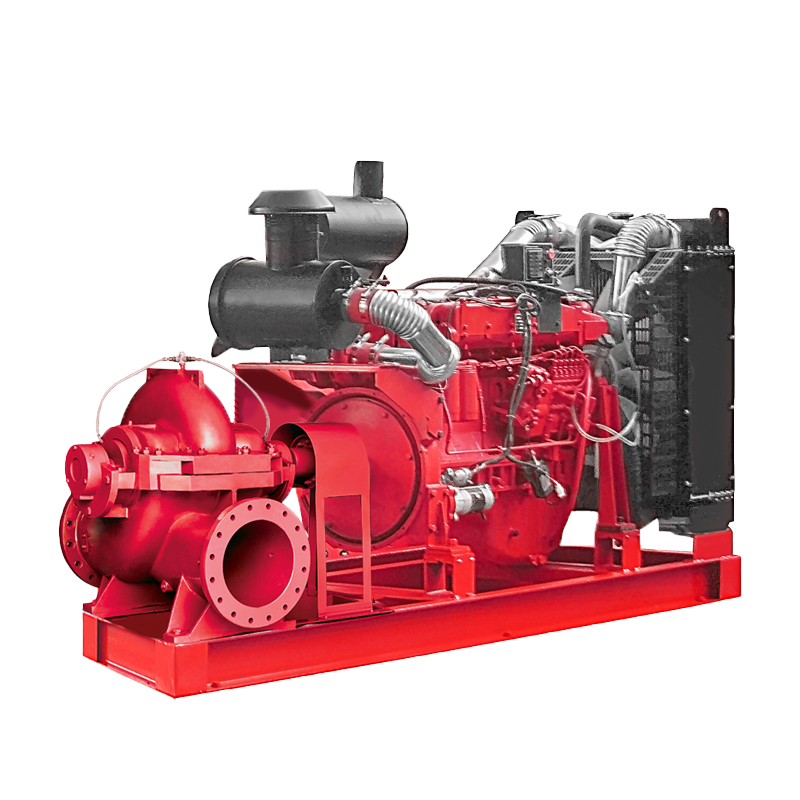

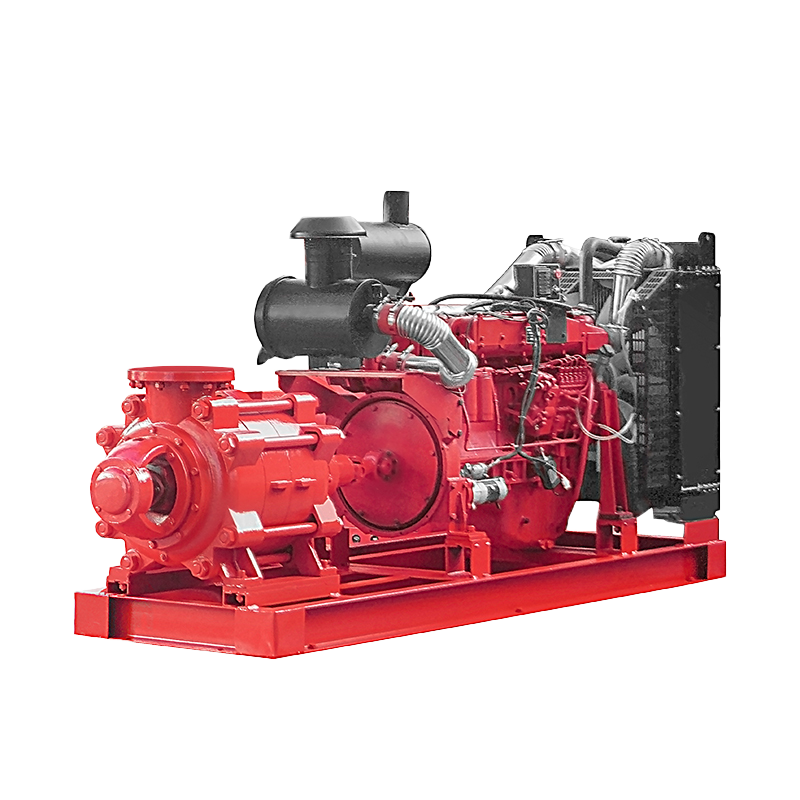

The modular design of suction fire pump sets makes installation simple. Each module can be installed independently or together. Each module can be fitted with electric or diesel engine motors for maximum safety and reliability. In addition, each module is available in a split case, multistage, and borehole configurations. To ensure safety and reliability, the pumps can be sized for specific building requirements. Installation of suction fire pump sets follows NFPA regulations.

Maintenance

There are a few important steps to follow when maintaining a suction fire pump set. Regular inspections and maintenance of the fire pump will prevent any problems from developing. Inspections should be conducted at least once a year. These inspections are visual examinations to ensure that everything is functioning properly. Tests should also be done to determine the pump's status and how it will work when called upon. By following the proper maintenance procedure, you can ensure the safety of your employees and your property.

When performing routine maintenance, be sure to check the piping that connects the fire pump to the water supply. NFPA 24 has specific guidelines for choosing the pipe materials used, the depth of cover for buried pipes, and acceptance testing. To prevent this, make sure that all the piping is in good condition. Once the piping system is in good condition, inspect the pump for leaks and deterioration.

English

English عربى

عربى

Fire Pump and System

Fire Pump and System Split Case Pump

Split Case Pump Engine and Pump

Engine and Pump Long Shaft Pump

Long Shaft Pump Multistage pump

Multistage pump Water Supplier System

Water Supplier System Sewage Pump

Sewage Pump Industrial Pump

Industrial Pump Self-Priming Pump

Self-Priming Pump Inline Pump

Inline Pump Domestic Pump

Domestic Pump Electric Motor

Electric Motor Borehole Pump

Borehole Pump