Multistage Pump: A Complete Guide to High-Pressure Fluid Transfer

A multistage pump is a centrifugal pump specifically designed to handle applications that require high pressure. By using multiple impellers in a series, multistage pumps progressively increase the pressure of the fluid, making them ideal for industries like water supply, power generation, chemical processing, and more. Their ability to deliver efficient and reliable performance has made them a popular choice for handling demanding fluid transfer needs.

What Is a Multistage Pump?

A multistage pump is a type of centrifugal pump that contains two or more impellers mounted on the same shaft. Each impeller works as an individual stage, and as the fluid passes through each stage, its pressure increases. This design allows multistage pumps to achieve high-pressure output while maintaining a consistent flow rate.

Multistage pumps are commonly used for applications involving long-distance fluid transfer, high-pressure requirements, or systems with significant elevation differences. These pumps can handle clean water, chemicals, and other low-viscosity fluids, making them versatile and indispensable for various industries.

How Does a Multistage Pump Work?

The working principle of a multistage pump is based on the centrifugal force generated by the high-speed rotation of impellers. Here’s how it operates:

1.Fluid Entry (Suction Stage):

The fluid enters the pump through the suction inlet and moves into the stage (impeller).

2.Pressure Increase (Through Multiple Stages):

The impeller increases the fluid pressure and transfers it to the next stage.

This process is repeated in each subsequent stage, progressively increasing the pressure.

3.Fluid Discharge:

After passing through all the stages, the high-pressure fluid exits the pump through the discharge outlet.

Each stage contributes to the overall pressure increase, while the flow rate remains relatively constant.

How to Choose the Right Multistage Pump

Selecting the right multistage pump is critical for achieving performance. Consider the following factors:

h3<>1. Pressure and Flow Requirements

Determine the required pressure and flow rate to ensure the pump can meet your system’s demands.

2. Fluid Properties

Assess the viscosity, temperature, and chemical composition of the fluid to select a pump with compatible materials.

3. Pump Orientation

Choose between horizontal or vertical configurations based on your installation space and system design.

4. Material Construction

Opt for corrosion-resistant materials like stainless steel for handling aggressive or abrasive fluids.

5. Energy Efficiency

Look for models with high efficiency to reduce energy consumption and operating costs.

6. Noise Levels

For applications in residential or noise-sensitive areas, select a pump designed for quiet operation.

7. Manufacturer Reliability

Purchase from a trusted manufacturer that offers a warranty, technical support, and spare parts.

A multistage pump is a powerful and efficient solution for high-pressure fluid transfer in various industries. Its ability to deliver consistent performance, handle a wide range of fluids, and operate efficiently makes it a top choice for applications such as water supply, boiler feed systems, HVAC, and chemical processing.

When selecting a multistage pump, consider factors like pressure requirements, fluid properties, and energy efficiency to find the fit for your needs. Regular maintenance will ensure reliable operation and extend the pump’s lifespan, providing long-term value for your investment.

English

English عربى

عربى

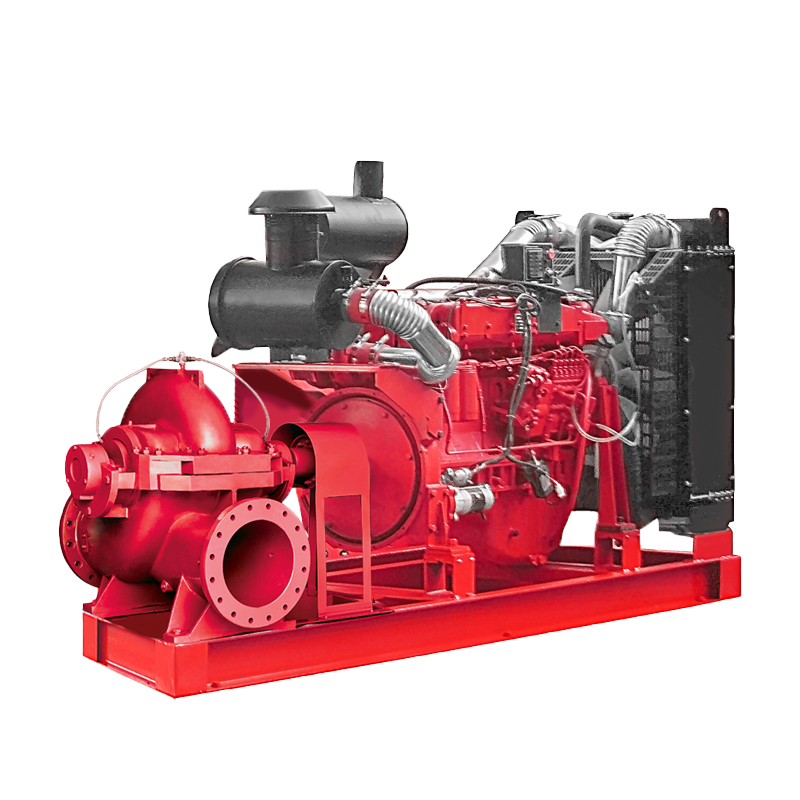

Fire Pump and System

Fire Pump and System Split Case Pump

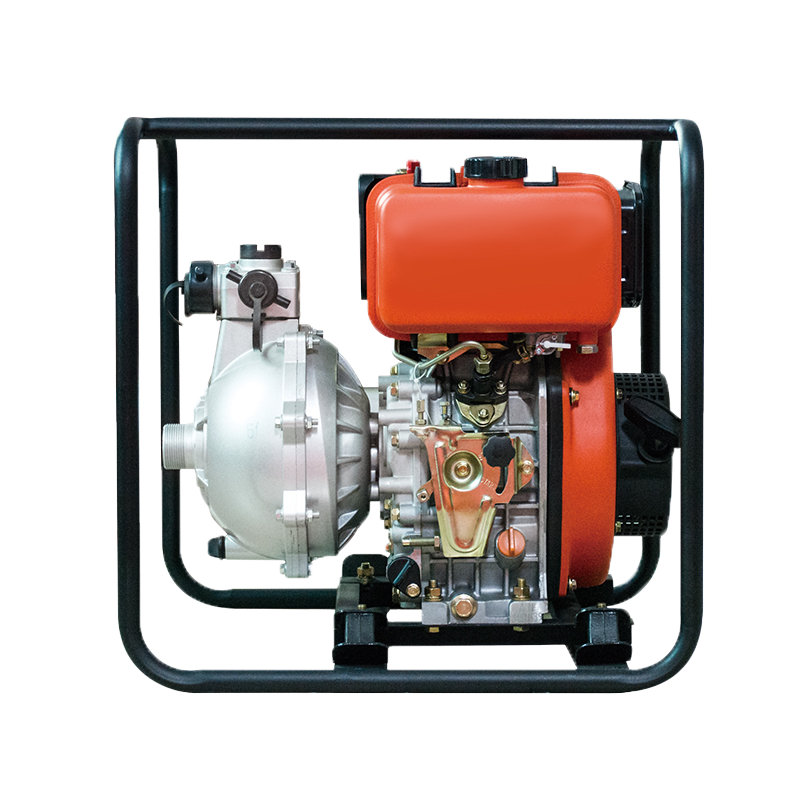

Split Case Pump Engine and Pump

Engine and Pump Long Shaft Pump

Long Shaft Pump Multistage pump

Multistage pump Water Supplier System

Water Supplier System Sewage Pump

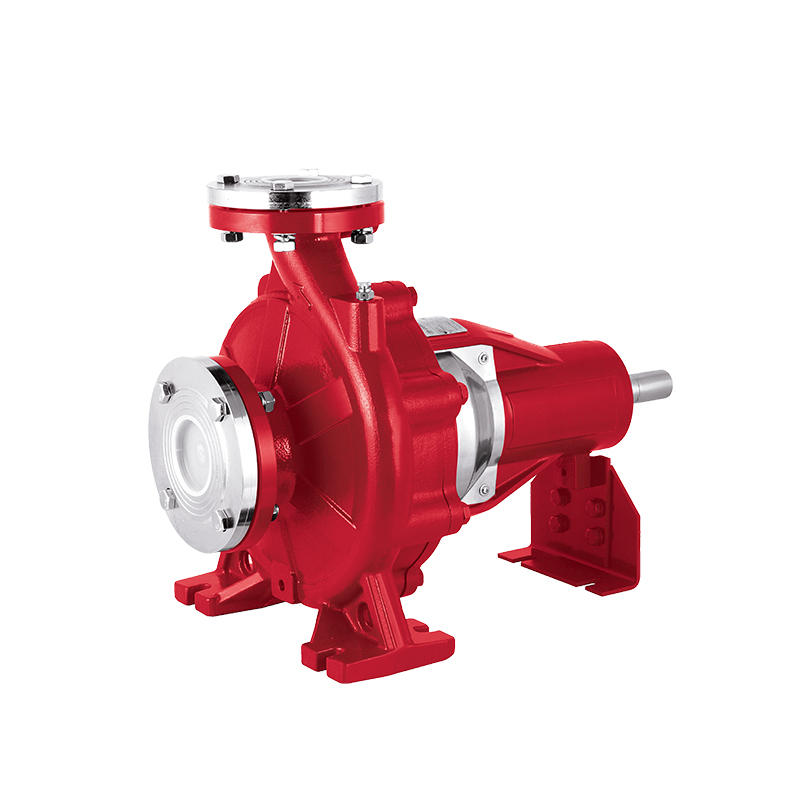

Sewage Pump Industrial Pump

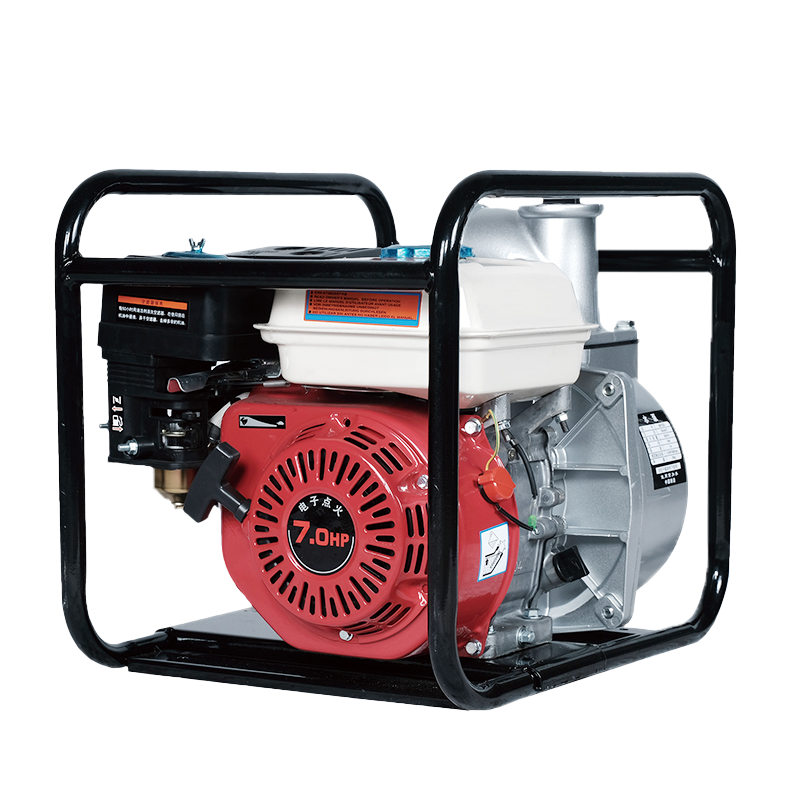

Industrial Pump Self-Priming Pump

Self-Priming Pump Inline Pump

Inline Pump Domestic Pump

Domestic Pump Electric Motor

Electric Motor Borehole Pump

Borehole Pump