Horizontal Centrifugal Pump: A Comprehensive Guide to Efficient Fluid Transfer

A horizontal centrifugal pump is one of the widely used pump types for fluid transfer across industries due to its efficiency, reliability, and versatility. Designed with a horizontal shaft, this pump is ideal for applications requiring consistent flow rates for water, chemicals, oil, and other liquids.

What Is a Horizontal Centrifugal Pump?

A horizontal centrifugal pump is a type of pump that uses centrifugal force to move fluids. It features a horizontally mounted shaft and a rotating impeller that increases the pressure and velocity of the fluid, allowing it to flow efficiently.

The pump is commonly used for applications involving clean or slightly contaminated liquids in industries such as water treatment, agriculture, chemicals, and HVAC systems. Thanks to its horizontal design, this pump is easy to install and maintain, making it a popular choice for various fluid transfer tasks.

How Does a Horizontal Centrifugal Pump Work?

The operation of a horizontal centrifugal pump is based on the principle of centrifugal force. Here’s a step-by-step explanation:

1.Fluid Entry (Suction Stage):

The fluid enters the pump through the suction inlet, typically located at the center of the impeller.

2.Centrifugal Action:

The impeller, powered by a motor, rotates at high speed, creating centrifugal force that pushes the fluid outward toward the edges of the impeller.

3.Pressure and Velocity Increase:

As the fluid moves outward, its velocity and pressure increase.

4.Fluid Discharge:

The pressurized fluid exits the pump through the discharge outlet, ready for transfer to the desired location.

This simple yet effective mechanism ensures steady fluid flow, making horizontal centrifugal pumps highly efficient for various applications.

Key Features of a Horizontal Centrifugal Pump

1. Horizontal Shaft Design

The shaft is mounted horizontally, enabling easy installation, inspection, and maintenance.

2. Single-Stage or Multi-Stage Options

Single-stage pumps are ideal for moderate pressure applications, while multi-stage pumps are suitable for high-pressure requirements.

3. Wide Material Compatibility

Available in various materials, such as cast iron, stainless steel, and plastic, to handle different types of fluids.

4. Flexible Configurations

Can be customized with different impeller designs and sealing options for specific applications.

5. Energy Efficiency

Designed to reduce energy consumption while maintaining performance.

6. Low Maintenance Requirements

Simple construction with minimal moving parts ensures long-term reliability.

Benefits of a Horizontal Centrifugal Pump

1. High Efficiency

Provides consistent and reliable performance for steady fluid transfer with minimal energy consumption.

2. Versatility

Suitable for a wide range of applications, from water supply to chemical processing and HVAC systems.

3. Compact and Stable Design

The horizontal layout provides stability and saves space, especially in installations with height constraints.

4. Ease of Maintenance

The horizontal shaft design makes it easy to access and replace components such as bearings, seals, and impellers.

5. Cost-Effective Operation

Its simple design and efficient operation minimize maintenance and energy costs.

6. Durability

Built with robust materials to withstand challenging operating conditions, including high temperatures and corrosive environments.

A horizontal centrifugal pump is a versatile and efficient solution for fluid transfer in various industries, from water supply to chemical processing and HVAC systems. Its compact design, reliability, and ability to handle diverse fluids make it an essential component in many operations.

When choosing a horizontal centrifugal pump, consider factors like flow rate, fluid properties, and material construction to ensure performance. Regular maintenance will help extend the pump’s lifespan, enhance efficiency, and reduce operational costs.

English

English عربى

عربى

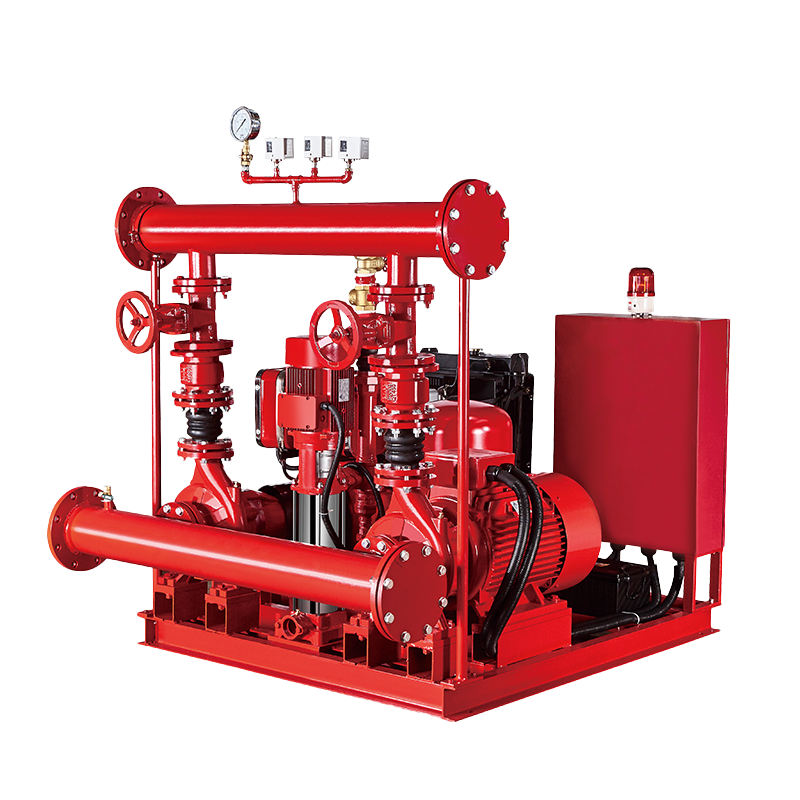

Fire Pump and System

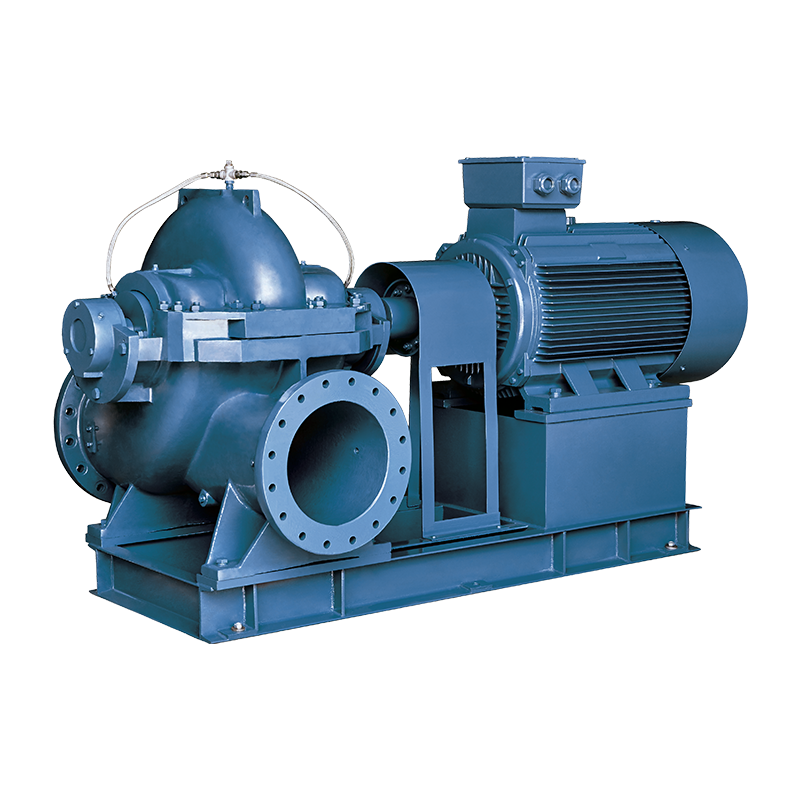

Fire Pump and System Split Case Pump

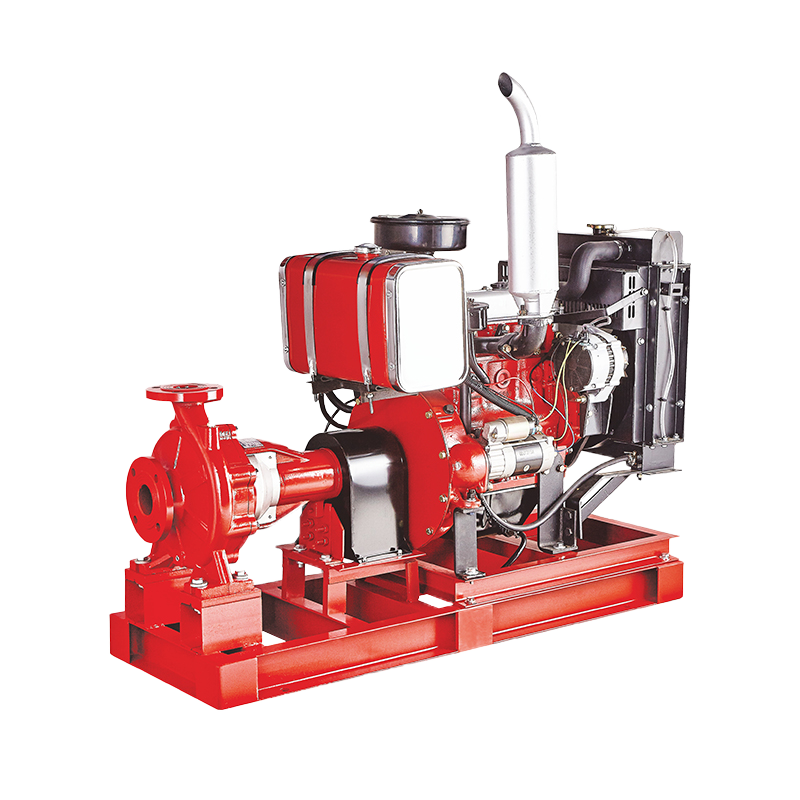

Split Case Pump Engine and Pump

Engine and Pump Long Shaft Pump

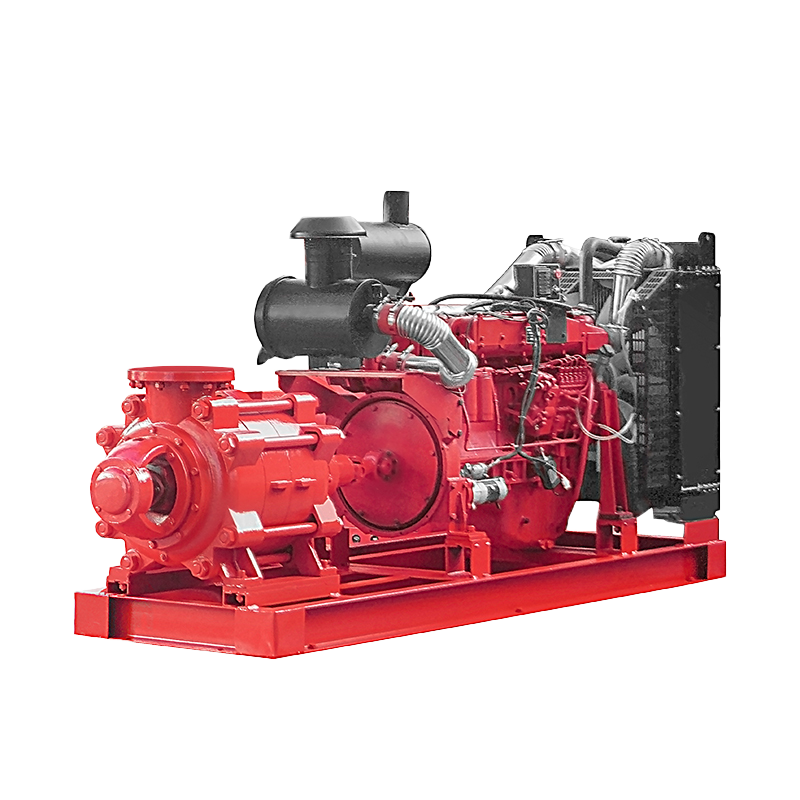

Long Shaft Pump Multistage pump

Multistage pump Water Supplier System

Water Supplier System Sewage Pump

Sewage Pump Industrial Pump

Industrial Pump Self-Priming Pump

Self-Priming Pump Inline Pump

Inline Pump Domestic Pump

Domestic Pump Electric Motor

Electric Motor Borehole Pump

Borehole Pump