If you need a self-priming pump to use in a chemical application, a self-priming pump may be the best option for you. It features an ejector on the suction side, which draws the liquid up to the elevation of the pump. These pumps are commonly referred to as peristaltic pumps, and they are also called submersible pumps. These pumps are typically powered by compressed air.

There are several types of self-priming pumps available. The LEO APSm is one such pump. This pump can be used to transfer clean water or other similar liquids. It can be used for sprinkling irrigation in a garden or lifting water from a well. These pumps are made with special anti-rust treatment and F grade insulating materials, so they are safe and effective for a variety of sewage-handling applications.

There are several ways to prevent the pump from not priming itself. One simple way is to install an auto shutdown or alarm that automatically shuts down the pump if it is not primed. Below is an example of this. You can choose to install your pump with a self-priming mechanism or a manual switch. This way, you can use it to pump fluid from a large container and prevent it from over-pressurizing.

A self-priming sewage pump is a diesel engine or electric motor-powered pump that does not require a bottom valve. Generally, the total weight of impurities in the medium is not more than 15 percent, and the specific weight of the medium is not more than 1240 kilograms per cubic meter. The pump's open impeller structure permits free pass of solids in sewage, and is suitable for light industry and urban diacharge projects.

The efficiency of self-priming pumps depends on the pump's impeller, which is a central part of the pump's design. The impeller's efficiency is influenced by the level of solids in the liquid, which can clog the recirculation port. This debris also reduces the pump's ability to produce a low-pressure zone. The internal clearances between the impeller and volute case increase with wear, and incorrect assembly can affect these clearances.

Another self-priming pump type is a self-priming pump. A self-priming pump must be re-primed after each pumping cycle. This feature is known as a "guaranteed re-primer" and is the most common self-priming pump type. A pump with a "guaranteed re-priming" feature will only need liquid once in order to work.

Self-priming pumps can be used in many different applications. These pumps are typically used for sewage treatment, construction dewatering, and flood control. All Pumps stocks a full line of self-priming pumps from manufacturers such as Gorman Rupp and Johnson. With so many self-priming pump options, finding the right self-priming pump for your application can be a simple process. It's best to start by browsing their selection.

Self-priming pumps are induced by blowing compressed air through a tapered pipe. This creates a vacuum that draws the air from the suction pipe and pump casing. To avoid a repeat self-priming operation, there is a non-return ball check valve upstream of the pump. By using this method, the pump is able to begin pumping as soon as the compressed air is released.

English

English عربى

عربى

Fire Pump and System

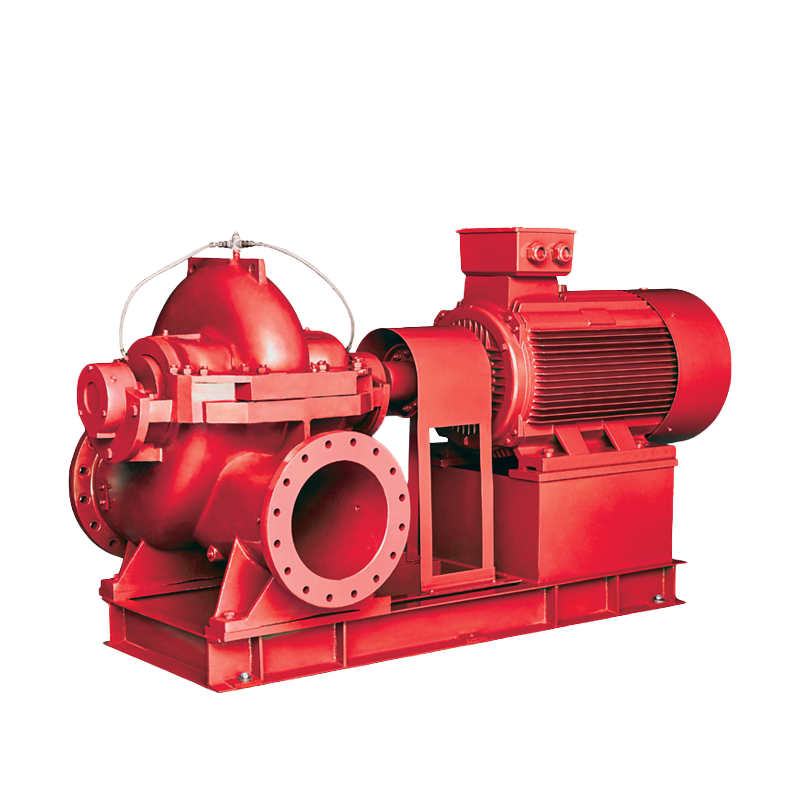

Fire Pump and System Split Case Pump

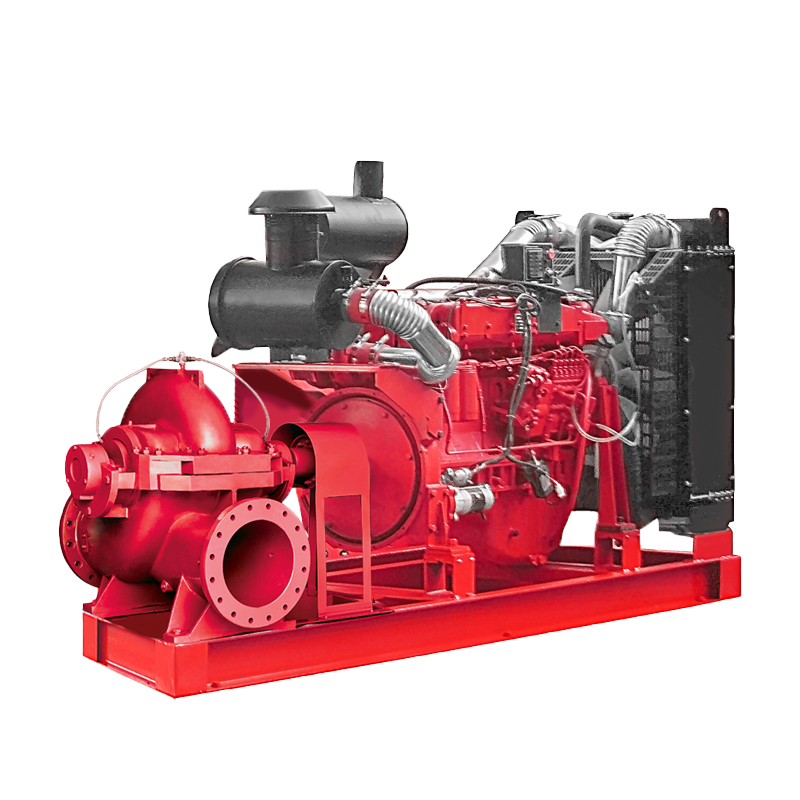

Split Case Pump Engine and Pump

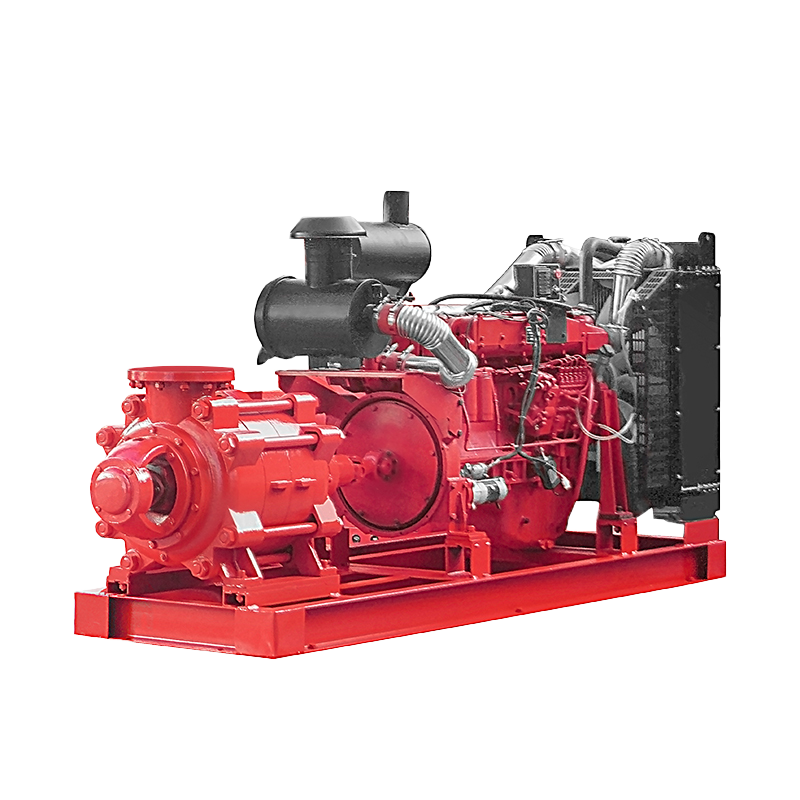

Engine and Pump Long Shaft Pump

Long Shaft Pump Multistage pump

Multistage pump Water Supplier System

Water Supplier System Sewage Pump

Sewage Pump Industrial Pump

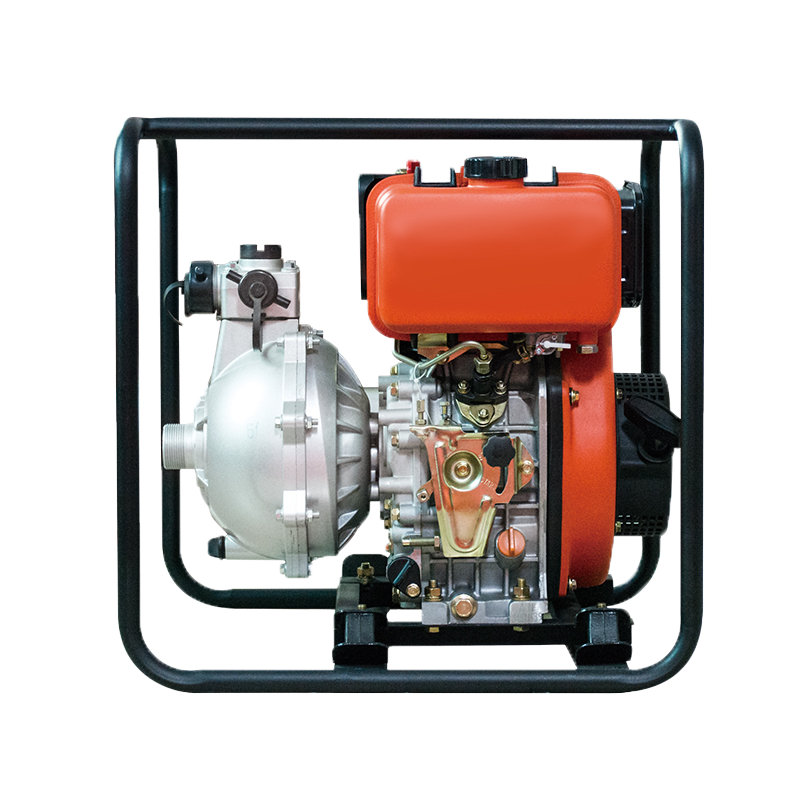

Industrial Pump Self-Priming Pump

Self-Priming Pump Inline Pump

Inline Pump Domestic Pump

Domestic Pump Electric Motor

Electric Motor Borehole Pump

Borehole Pump