Pipeline Pumps: Powering Fluid Transportation and Distribution

Introduction:

Pipeline pumps are vital components in fluid transportation systems, enabling the efficient movement of liquids over long distances. In this article, we will explore the functionality, types, and applications of pipeline pumps, shedding light on their essential role in various industries.

-

Understanding Pipeline Pumps:

Pipeline pumps are designed to propel fluids through pipelines, overcoming friction and maintaining a steady flow. They provide the necessary pressure and energy to ensure the efficient transportation of liquids such as water, oil, gas, and chemicals. -

Types of Pipeline Pumps:

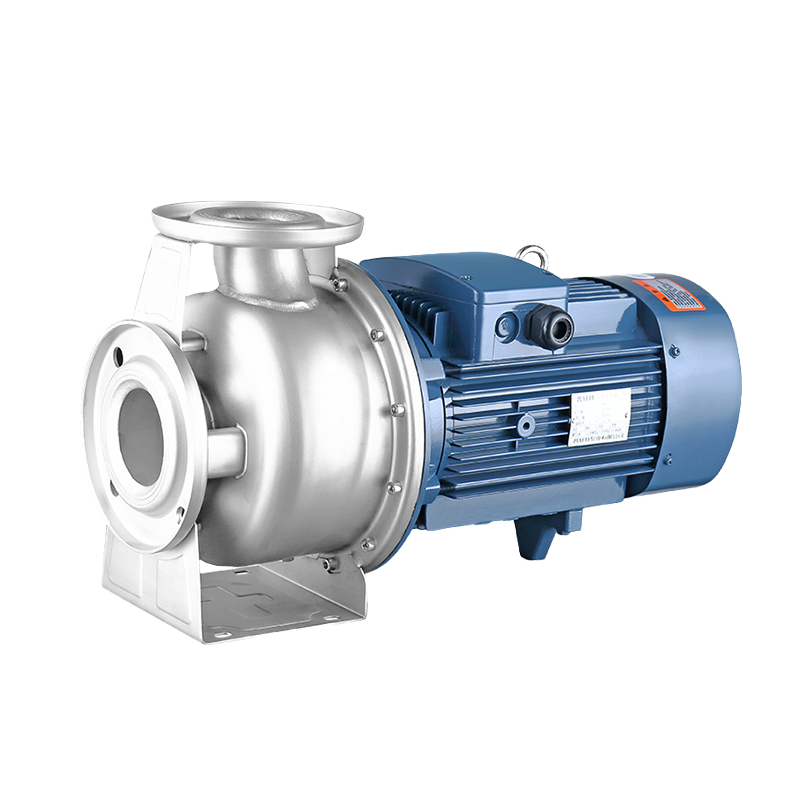

a. Centrifugal Pumps: These pumps utilize centrifugal force to generate pressure and move fluids. They are widely used in pipeline applications due to their high flow rates and versatility.

b. Positive Displacement Pumps: These pumps operate by trapping and displacing fluid through mechanical means, offering precise control over flow rates and suitable for handling viscous liquids or variable process conditions.

c. Axial Flow Pumps: These pumps are designed to move large volumes of fluid at low pressure differentials. They are commonly used in scenarios where a high flow rate is required, such as in water supply systems or irrigation. -

Key Components and Operation:

a. Impeller: The impeller is a rotating component responsible for imparting energy to the fluid. It accelerates the liquid and transfers it to the pump's discharge.

b. Casing: The casing surrounds the impeller and directs the flow of liquid, ensuring a smooth and efficient path.

c. Motor or Driver: The motor or driver provides the necessary power to drive the pump and maintain consistent fluid flow.

d. Control Systems: Pipeline pumps may incorporate various control systems to monitor and regulate flow rates, pressure, and operating conditions. -

Applications of Pipeline Pumps:

a. Oil and Gas Industry: Pipeline pumps play a critical role in transporting crude oil, refined products, and natural gas across vast distances, ensuring a steady supply to refineries and distribution networks.

b. Water Distribution: Pipeline pumps are used in water supply systems for cities, towns, and irrigation projects, ensuring a reliable and continuous flow of water to meet the demands of residential, commercial, and agricultural sectors.

c. Chemical Processing: Pipeline pumps handle the transportation of various chemicals within industrial facilities, ensuring precise delivery and maintaining the integrity of the manufacturing process.

d. Municipal Infrastructure: These pumps are employed in wastewater treatment plants, aiding in the movement of wastewater through treatment processes and facilitating efficient disposal. -

Maintenance and Efficiency:

Regular maintenance, including inspection, lubrication, and performance monitoring, is crucial to ensure the optimal operation of pipeline pumps. Implementing energy-efficient designs and technologies can also enhance their performance, reducing operational costs and minimizing environmental impact.

Conclusion:

Pipeline pumps serve as the backbone of fluid transportation systems, enabling the efficient movement of liquids across various industries. Understanding their types, components, and applications is essential to appreciate their crucial role in ensuring reliable and consistent fluid flow over long distances.

English

English عربى

عربى

Fire Pump and System

Fire Pump and System Split Case Pump

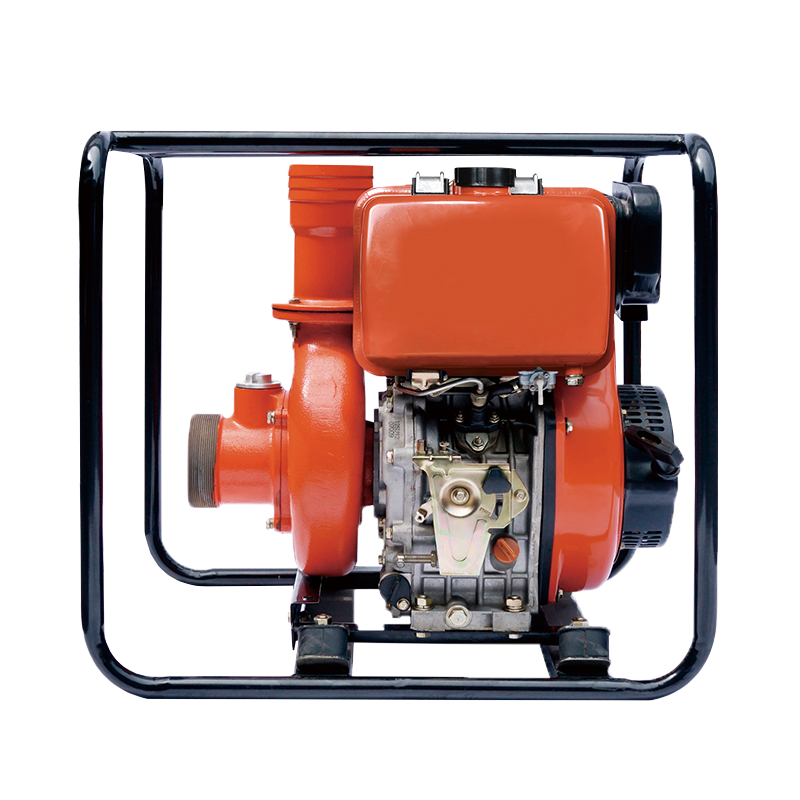

Split Case Pump Engine and Pump

Engine and Pump Long Shaft Pump

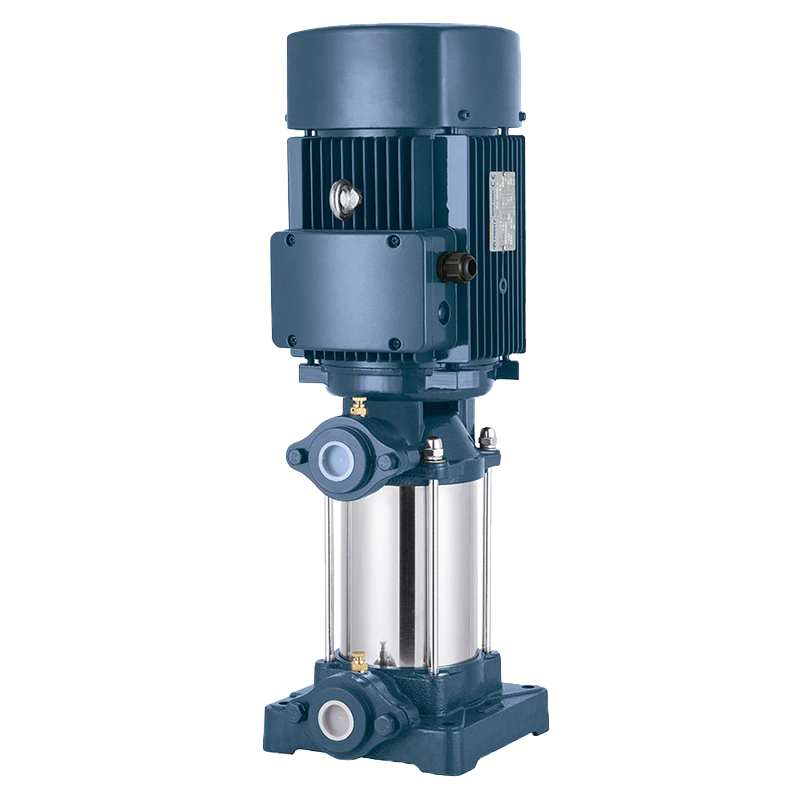

Long Shaft Pump Multistage pump

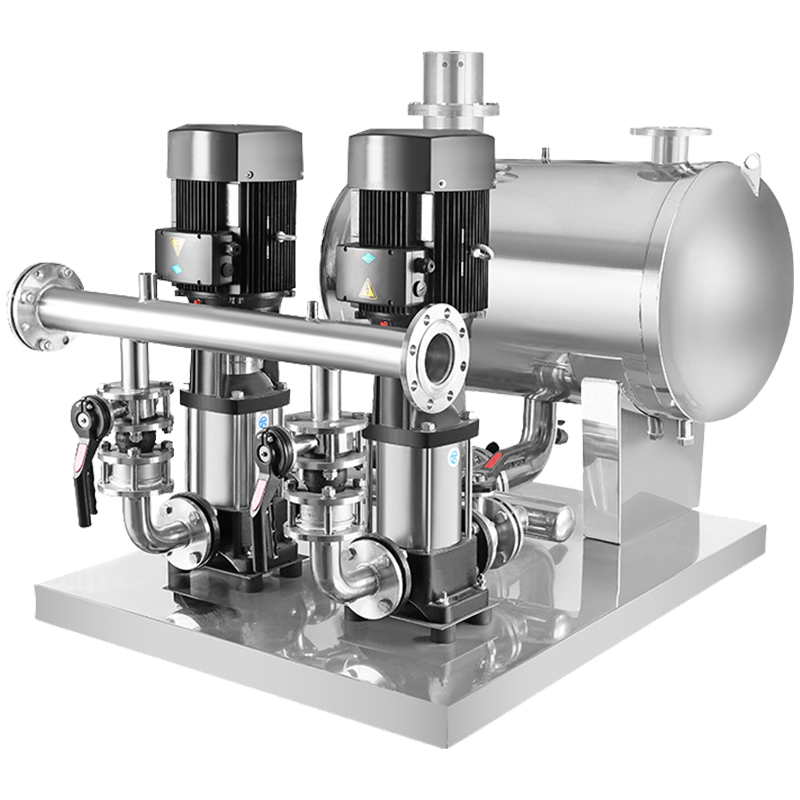

Multistage pump Water Supplier System

Water Supplier System Sewage Pump

Sewage Pump Industrial Pump

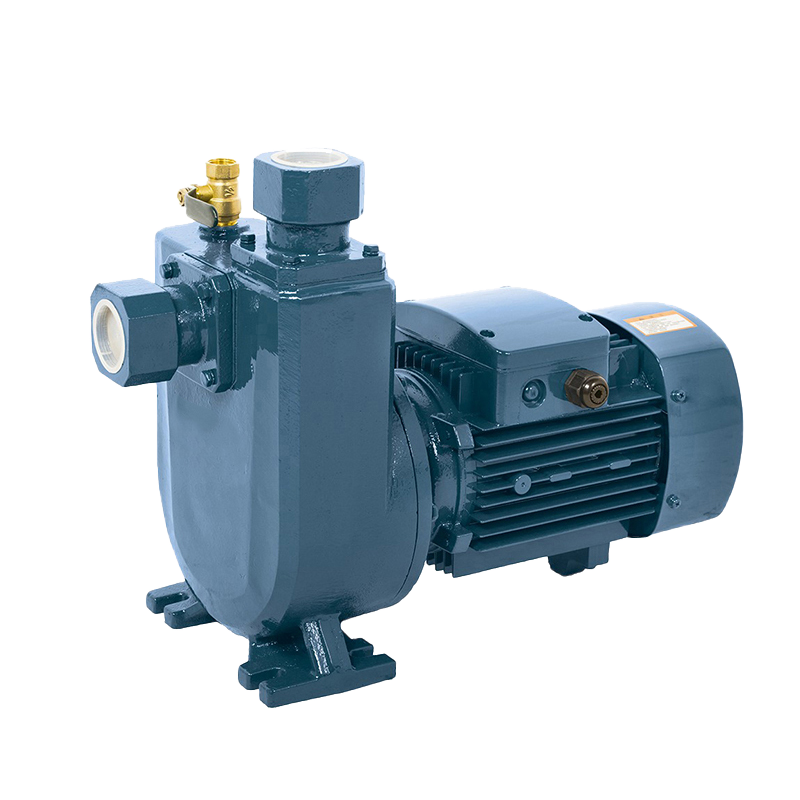

Industrial Pump Self-Priming Pump

Self-Priming Pump Inline Pump

Inline Pump Domestic Pump

Domestic Pump Electric Motor

Electric Motor Borehole Pump

Borehole Pump