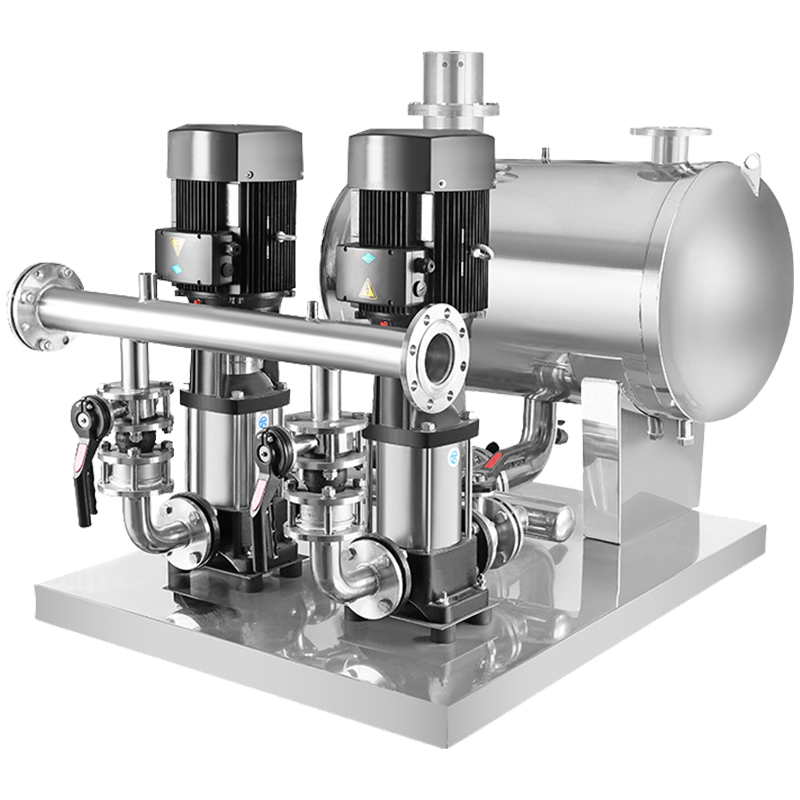

The vertical multi-stage pump has become the unsung hero in various industries, providing a compact, efficient, and reliable solution

for fluid handling. This non-self-priming vertical multi-stage centrifugal pump is designed with innovation in mind, offering a plethora

of features that make it a standout choice. Let's dive into the intricacies of this pump, exploring its working principle, key features,

applications, and why it's the go-to choice in multiple scenarios.

Working Principle: Harnessing Centrifugal Force for Precision Fluid Handling

The working principle of the vertical multi-stage pump is centered around the dynamic interplay between the motor, impeller, and fluid.

As the motor propels the impeller to rotate at high speeds, the liquid within the impeller is propelled outward along the flow path between

the blades, guided by the centrifugal force. This process significantly increases both pressure and speed. The liquid is then directed to the

next-stage impeller through the flow channel of the guide housing, amplifying pressure energy. This sequential process, where impellers are

stacked step by step, results in the pump generating a specific lift.

As the motor propels the impeller to rotate at high speeds, the liquid within the impeller is propelled outward along the flow path between

the blades, guided by the centrifugal force. This process significantly increases both pressure and speed. The liquid is then directed to the

next-stage impeller through the flow channel of the guide housing, amplifying pressure energy. This sequential process, where impellers are

stacked step by step, results in the pump generating a specific lift.

Features that Redefine Fluid Handling Efficiency:

Hydraulic Excellence:

The vertical type adopts an outstanding hydraulic model and employs advanced manufacturing technology, elevating the overall

performance and service life of the pump.

performance and service life of the pump.

Reliable Shaft Seal:

Utilizing mechanical seals made of cemented carbide and fluororubber for the shaft seal enhances the reliability of pump operation,

even in challenging temperature conditions.

even in challenging temperature conditions.

Corrosion Resistance:

Crafted with flow-passing parts stamped and welded from stainless steel plates (304/316), the pump is aptly suited for mildly corrosive

media, ensuring durability and longevity.

media, ensuring durability and longevity.

Compact, Lightweight, and Quiet:

The overall structure is designed to be compact, small in size, and light in weight, while maintaining low noise levels. This not only saves

space but also contributes to a quiet working environment.

space but also contributes to a quiet working environment.

Energy-Saving Convenience:

The adoption of a standard vertical motor ensures that users can easily equip the pump with motors tailored to their specific needs,

promoting energy efficiency.

promoting energy efficiency.

Intelligent Protection:

Intelligent protectors can be integrated based on user needs, effectively shielding the pump from potential issues such as dry running,

phase loss, overload, and more.

phase loss, overload, and more.

Pipeline Integration:

The water inlet and outlet are strategically positioned on the same horizontal line as the pump base, allowing for direct integration into

pipelines with utmost convenience.

pipelines with utmost convenience.

Applications: Where Efficiency Meets Diverse Needs

Water Supply:

Filtration and transportation in water plants

District water delivery

Main pipe pressurization

High-rise building pressurization

Industrial Pressurization:

Process water systems

Cleaning systems

High-pressure flushing systems

Fire protection systems

Industrial Liquid Transportation:

Cooling and air conditioning systems

Boiler water supply and condensation systems

Machine tool accessories

Acidic and alkaline media transportation

Water Treatment:

Water Treatment:

Ultrafiltration systems

Reverse osmosis systems

Distillation systems

Separator and swimming pool water treatment systems

Irrigation:

Farmland irrigation

Sprinkler irrigation

Drip irrigation

Transport Medium: Navigating Fluids with Precision

Thin, clean, non-flammable, and non-explosive mediums without solid particles or fibers.

Examples include mineral water, softened water, pure water, clear oil, and other light chemical media.

The pump's stainless steel construction allows it to handle mildly corrosive media with ease.

Scope of Application: Tailoring Solutions for Varied Needs

Main pump for variable frequency water supply systems.

Ordinary water supply and boiler water supply.

High-pressure washing and R/O filter devices.

Hot and cold water circulation.

Manufacturing engineering equipment and beverage processing equipment.

In conclusion, the vertical multi-stage pump stands as a testament to efficiency, reliability, and versatility in fluid handling applications. Whether

it's boosting water pressure in high-rise buildings or facilitating precise liquid transportation in industrial processes, this pump is the key to

unlocking a new era of fluid handling excellence. Choose innovation, choose the vertical multi-stage pump.

it's boosting water pressure in high-rise buildings or facilitating precise liquid transportation in industrial processes, this pump is the key to

unlocking a new era of fluid handling excellence. Choose innovation, choose the vertical multi-stage pump.

English

English عربى

عربى

Fire Pump and System

Fire Pump and System Split Case Pump

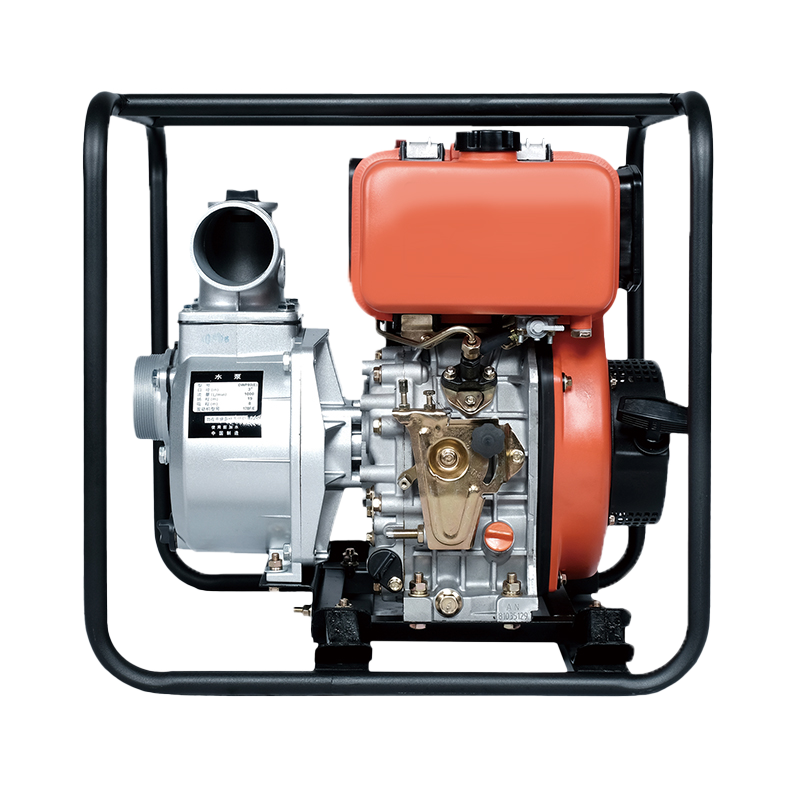

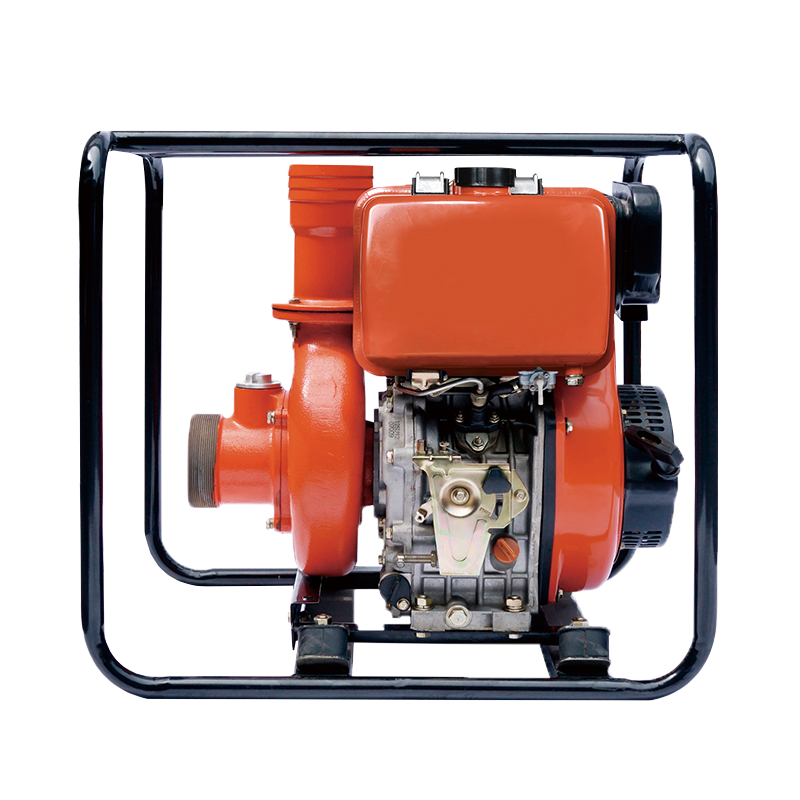

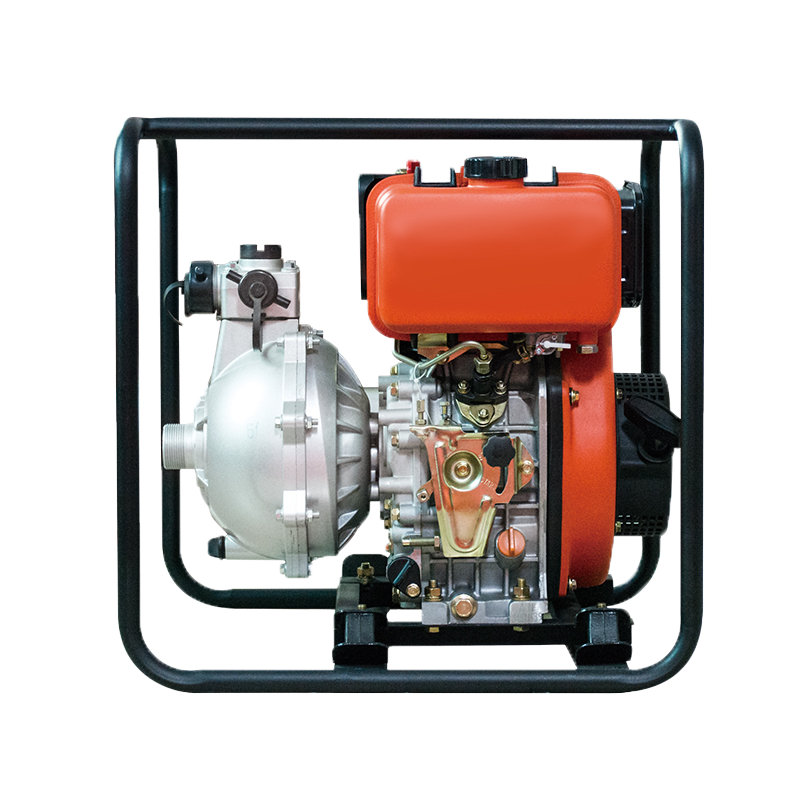

Split Case Pump Engine and Pump

Engine and Pump Long Shaft Pump

Long Shaft Pump Multistage pump

Multistage pump Water Supplier System

Water Supplier System Sewage Pump

Sewage Pump Industrial Pump

Industrial Pump Self-Priming Pump

Self-Priming Pump Inline Pump

Inline Pump Domestic Pump

Domestic Pump Electric Motor

Electric Motor Borehole Pump

Borehole Pump