Centrifugal Pumps: The Ultimate Guide to Efficient Fluid Handling

Centrifugal pumps are among the widely used pumps in industries such as water supply, chemical processing, power generation, and oil and gas. Known for their high efficiency, reliability, and versatility, centrifugal pumps are essential for transferring liquids in a wide range of applications.

What Is a Centrifugal Pump?

A centrifugal pump is a mechanical device designed to move liquids by converting rotational energy from a motor into kinetic energy. This energy is used to increase the velocity of the fluid, which is then converted into pressure to move the liquid through a system.

Centrifugal pumps are widely used for handling low-viscosity fluids such as water, chemicals, and light oils. They are ideal for applications requiring high flow rates and moderate pressure, making them a versatile solution for various industries.

Benefits of Centrifugal Pumps

Centrifugal pumps offer numerous advantages, making them a popular choice for fluid handling systems:

1. High Efficiency

Capable of handling large volumes of fluid with minimal energy consumption.

2. Simple Design

Fewer moving parts make them easy to operate, maintain, and repair.

3. Cost-Effective

Affordable initial cost and low operational expenses compared to other pump types.

4. Versatility

Suitable for a wide range of liquids, including water, chemicals, and oils.

5. Continuous Operation

Designed for smooth, uninterrupted fluid flow in various systems.

6. Durability

Constructed with robust materials to withstand harsh industrial environments.

Applications of Centrifugal Pumps

Centrifugal pumps are used across a variety of industries due to their efficiency and reliability:

1. Water Supply and Distribution

Widely used in municipal water systems, irrigation, and residential water supply.

2. Chemical Processing

Handle aggressive chemicals, solvents, and process fluids in manufacturing plants.

3. Oil and Gas Industry

Transport crude oil, refined products, and other fluids in petroleum systems.

4. Power Generation

Circulate cooling water and supply water to boilers in power plants.

5. HVAC Systems

Used to move water or refrigerants in heating, ventilation, and air conditioning systems.

6. Food and Beverage Industry

Transfer liquids like milk, juices, and other beverages while maintaining hygiene standards.

7. Mining and Construction

Dewater mines, transfer slurries, and supply water to construction sites.

Centrifugal pumps are a cornerstone of fluid handling systems across a wide range of industries. Their high efficiency, versatility, and reliability make them a top choice for applications involving water, chemicals, and other low-viscosity liquids.

When selecting a centrifugal pump, consider factors like flow rate, pressure, and material compatibility to find the solution for your needs. Regular maintenance will ensure your pump operates efficiently and lasts for years to come.

English

English عربى

عربى

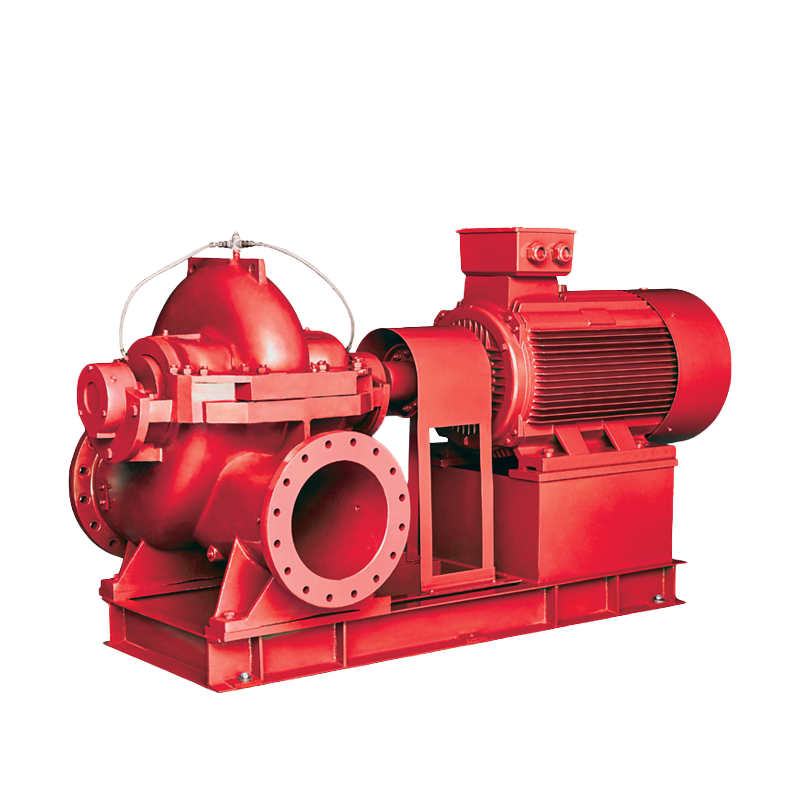

Fire Pump and System

Fire Pump and System Split Case Pump

Split Case Pump Engine and Pump

Engine and Pump Long Shaft Pump

Long Shaft Pump Multistage pump

Multistage pump Water Supplier System

Water Supplier System Sewage Pump

Sewage Pump Industrial Pump

Industrial Pump Self-Priming Pump

Self-Priming Pump Inline Pump

Inline Pump Domestic Pump

Domestic Pump Electric Motor

Electric Motor Borehole Pump

Borehole Pump