Submersible water pumps are one of the most efficient ways to move fluids. They are often used for pump-based irrigation systems, as well as to move sewage from buildings and wells. However, they do require special maintenance. It is important to know the different types of submersible water pumps available. This will help you determine the best type for your application.

Stainless steel submersible pumps are excellent for draining dirty water. In addition, they are easy to clean and are resistant to rust. Moreover, they work well with hot and slightly acidic water. Submersible pumps are often used to pump water from shallow wells. In addition, they can also be used to irrigate a mid-sized garden. The cost and maintenance of these pumps can be quite high, however, so it is essential to find out more about them before buying.

Submersible pumps are typically cylindrical in shape and are completely sealed. They are hermetically sealed. Unlike centrifugal pumps, they do not require priming. A submersible water pump is also designed to run for long periods of time without needing any electricity.

Submersible pumps are commonly seen in the United States. They can be found in homes, farms, and businesses, as well as in many other locations. There are several different types of pumps available, so you will need to find the right one for your specific application. If you are looking for a submersible pump, you should first determine the amount of horsepower you need. Pumps with higher horsepower require less running and provide greater performance. You may need more horsepower if you are planning to install a new appliance or if you plan to transport more water.

The pump cable is also a crucial part of a submersible pump. Most pumps use two or three wire cables. Each of these wires is usually color-coded for easy identification. Some of these cables also include power conductors for the pump motor. Others may require zip ties 10 feet apart. Another important component of a submersible water pump is a safety rope. This rope ensures the integrity of the pipe and prevents the pump from being disconnected.

It is vital to select a submersible pump with a high-quality seal. Poor seals can reduce the life of the pump. For example, if you have a pump with an aluminum seal, it will wear down much quicker than a pump with a stainless steel seal. Similarly, sediment can wear down the bearings.

Another important factor is the flow rate of the pump. Different models have different flow rates. To find out the flow rate of your pump, you can check its identification plate. Many manufacturers also have a chart that helps you decide which pump is right for your needs. Depending on your location, you might also need a larger pump. If you have a large farm or a well that is deep, you might need a heavy-duty pump. On the other hand, if you only need a small pump, you can purchase a model that only needs a small amount of energy.

English

English عربى

عربى

Fire Pump and System

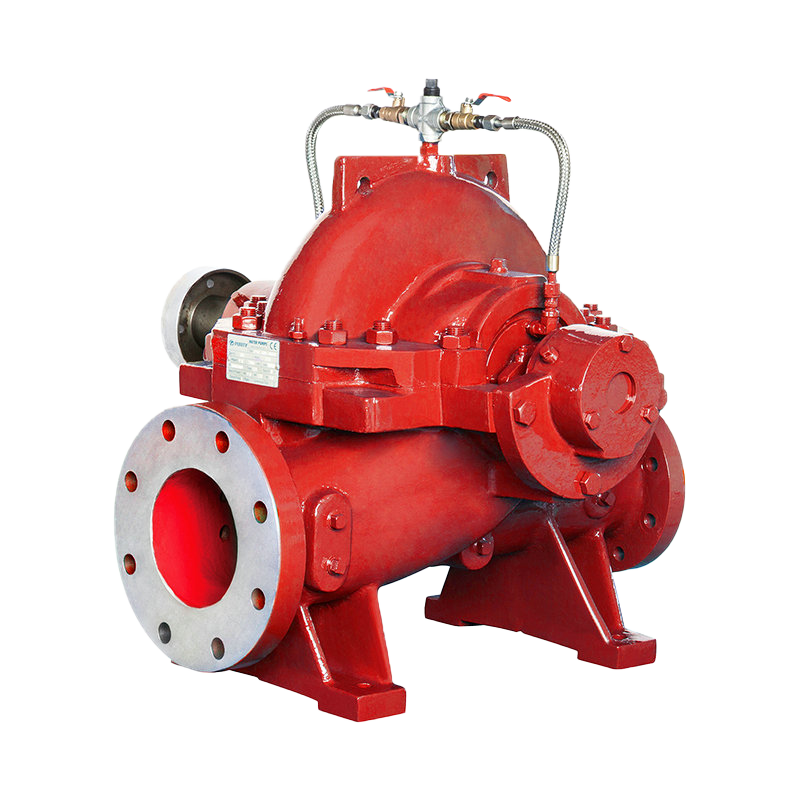

Fire Pump and System Split Case Pump

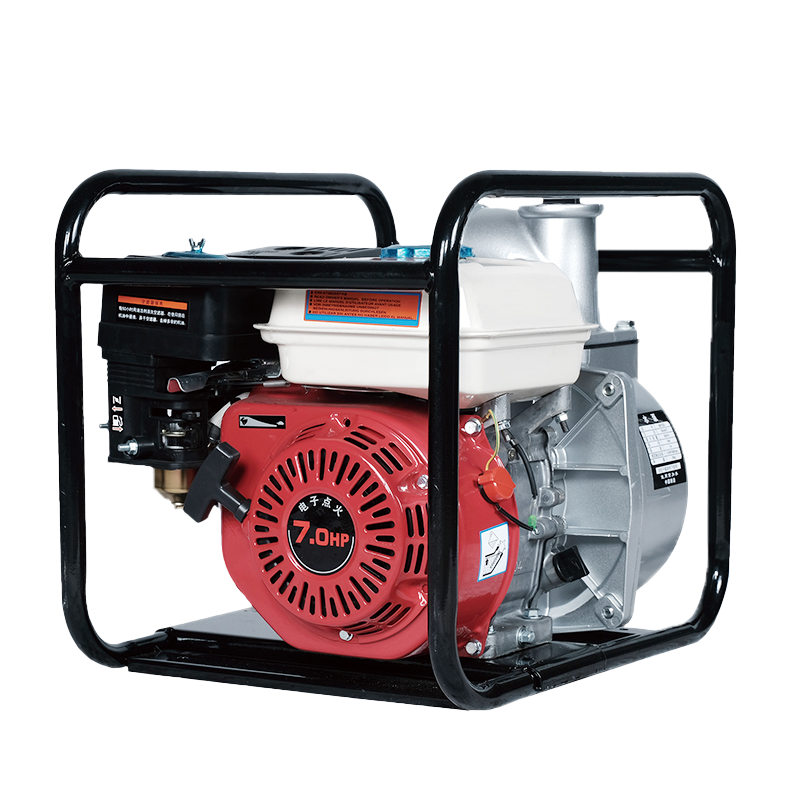

Split Case Pump Engine and Pump

Engine and Pump Long Shaft Pump

Long Shaft Pump Multistage pump

Multistage pump Water Supplier System

Water Supplier System Sewage Pump

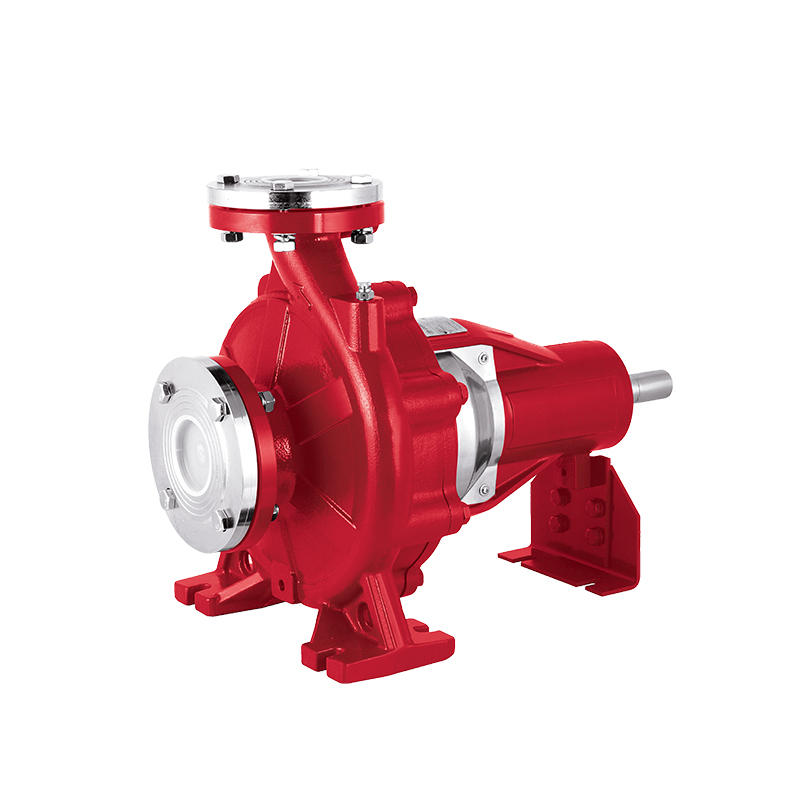

Sewage Pump Industrial Pump

Industrial Pump Self-Priming Pump

Self-Priming Pump Inline Pump

Inline Pump Domestic Pump

Domestic Pump Electric Motor

Electric Motor Borehole Pump

Borehole Pump