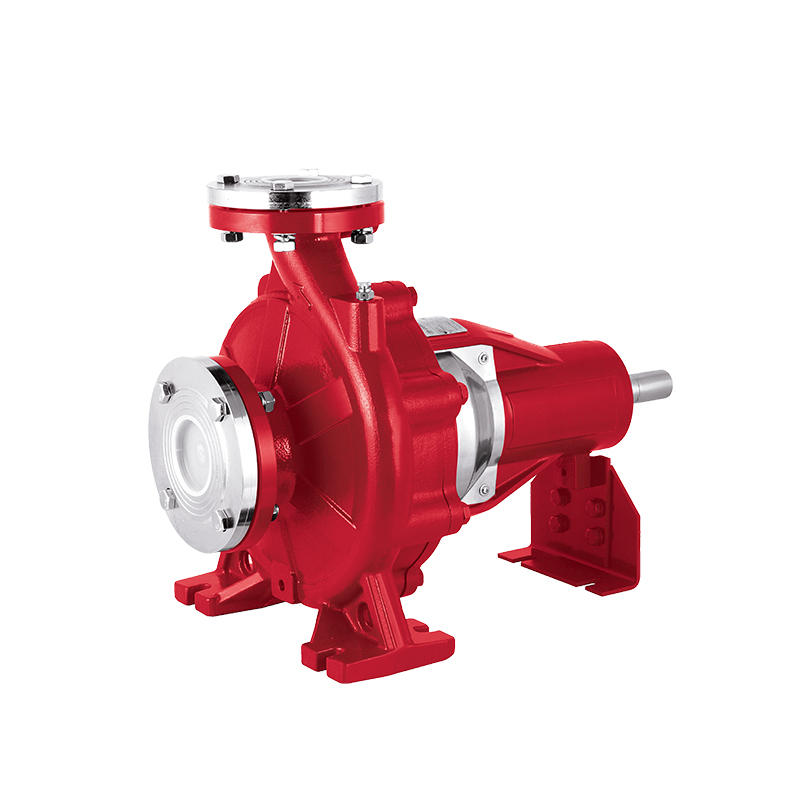

The end suction centrifugal pump is a simple and versatile tool that is used for fluid transfer. It is an economical option with few moving parts and requires little maintenance. End suction pumps are used for many applications, from chemical and food processing to oil services. Depending on the equipment used, the end suction pump can be closed or open. These pumps are typically designed to meet specific standards. However, they are not right for every application.

There are several differences between end suction centrifugal pumps. The end suction pump sucks in axially and horizontally and discharges radially. The pump casings and impellers are heavy and are able to withstand high working pressures and high levels of vibration. End suction pumps have a single-stage design and are usually made of cast iron or bronze. Because of their design, they are able to handle moderately high water flows.

The end suction centrifugal pumps come with a number of features and are ideal for a wide range of applications. These pumps can handle dirty water, have high temperatures, and be designed for continuous duty. In addition to these benefits, end suction centrifugal pumps are economical, making them a great option for a wide range of applications.

An end suction centrifugal pump can handle higher working pressures than a between-bearing pump. This pump is generally heavier and more expensive than an end suction pump. The end suction pump has a longer lifespan, but the cost of maintenance may outweigh the initial savings. The upside to an end suction pump is that its internal components can be easily accessed. Unlike end suction pumps, the split case pump is easy to maintain.

The end suction centrifugal pump can be divided into two distinct types, double-suction and single-suction. A double-suction pump has a sealed cavity on both sides of the impeller, and is better at anti-cavitation than a single-suction pump. However, the double-suction pump also has a low flow rate to reduce the risk of cavitation.

End suction centrifugal pumps are the most basic form of centrifugal pumps. They have a single impeller and a casing at one end. These pumps can handle many types of fluids, from water to abrasive slurries and corrosive chemicals. These pumps are commonly used for pumping water, abrasive slurries, and high-pressure viscous oils and slurries.

MP provides single-stage horizontal end-suction centrifugal pumps. The single-stage pumps use an open or enclosed-vane style impeller. A centrifugal pump transfers energy from a driver to kinetic energy in the liquid. The energy given to the liquid corresponds to its velocity at the tip of the impeller. The bigger the impeller, the greater the energy transferred. Compared to positive displacement pumps, centrifugal pumps do not require relief valves.

English

English عربى

عربى

Fire Pump and System

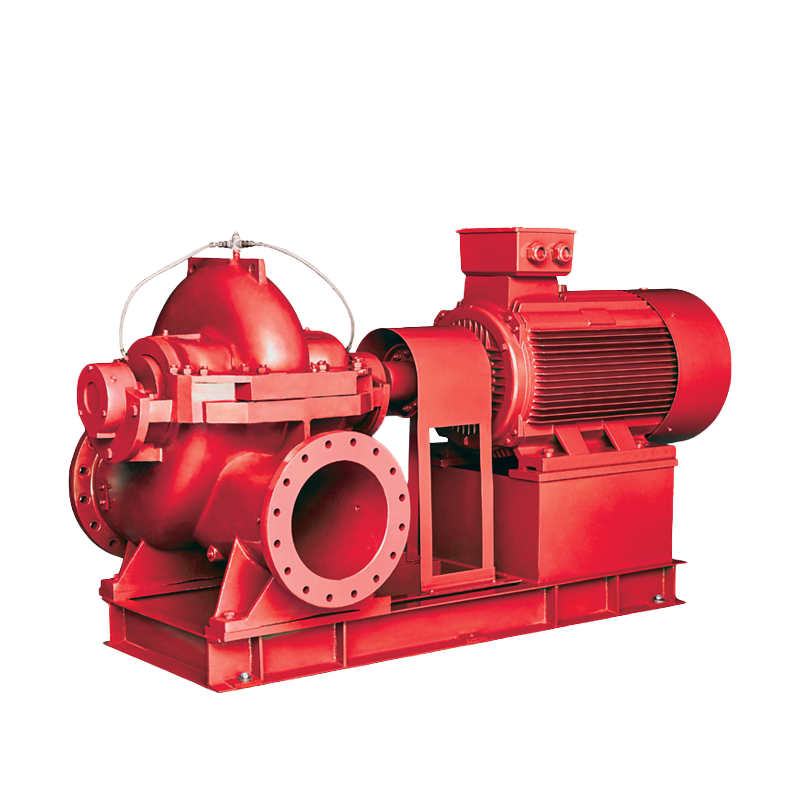

Fire Pump and System Split Case Pump

Split Case Pump Engine and Pump

Engine and Pump Long Shaft Pump

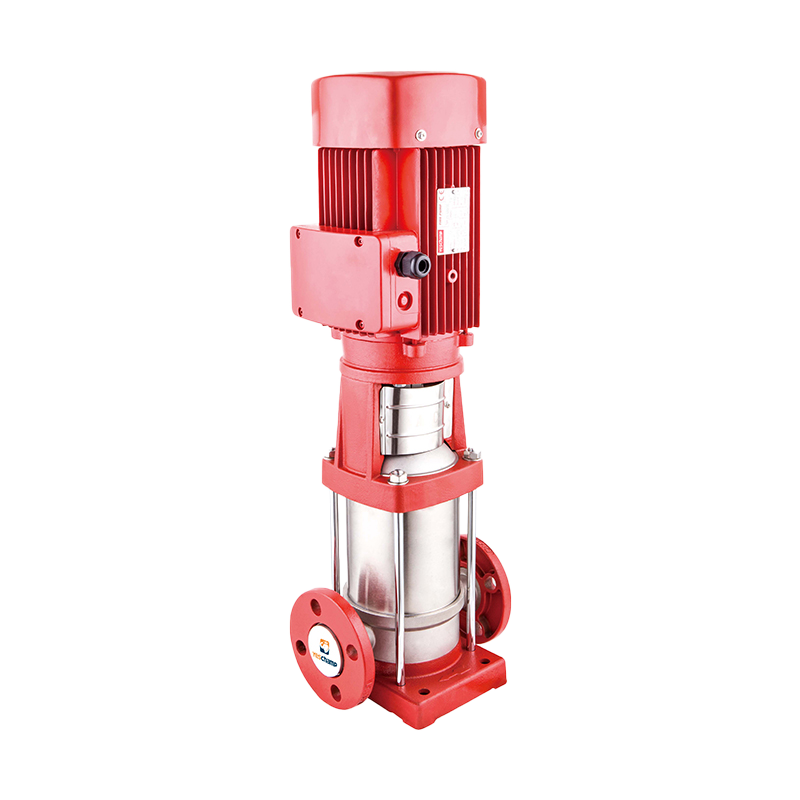

Long Shaft Pump Multistage pump

Multistage pump Water Supplier System

Water Supplier System Sewage Pump

Sewage Pump Industrial Pump

Industrial Pump Self-Priming Pump

Self-Priming Pump Inline Pump

Inline Pump Domestic Pump

Domestic Pump Electric Motor

Electric Motor Borehole Pump

Borehole Pump