When selecting a pump, it is important to consider its application. Some applications require corrosive liquids, and others require pumps that can withstand milder conditions. For example, hydrofluoric acid is frequently pumped in the pulp and paper industry. In other applications, corrosive media require pumps made of graphite monolithic ceramic or composite materials. If corrosive liquids are expected to pass through the pump, it is important to consult a metallurgist for guidance.

Generally, centrifugal pumps consist of an impeller. This is the rotating part of the pump, and is attached to a shaft by an electric motor. The impeller is covered with a watertight casing, and is responsible for imparting velocity to liquid.

Horizontal centrifugal pumps are easy to install and maintain. They feature easy access to internal parts, and can be coupled with external accessories. Horizontal pumps are larger than vertical pumps, and have lower working temperatures and pressures. There are several types of centrifugal pumps: single-stage pumps, double-stage pumps, and multistage pumps. Single-stage pumps feature a single impeller, while double-stage pumps have two impellers.

End-suction pumps handle clean or dirty liquids. They are used in many industries, including refrigerant and cryogenics. They can also handle thin liquids and solids. Some of them can even be used in corrosive services. When choosing a pump, it is important to consider its application.

Radial pumps are similar to horizontal pumps, but they rotate 90 degrees. They are used when pressure is required to reduce the flow of fluid. In addition, radial pumps are able to handle higher pressures. They also handle higher flow rates. These pumps are more efficient than horizontal pumps.

The three basic types of centrifugal pumps include: centrifugal, horizontal, and vertical centrifugal pumps. The difference in these three types is the kinetic energy of the impeller. As the impeller rotates, the pressure head of the liquid is increased. This fluid is directed through the piping system. Ultimately, the liquid is pumped away from the pump by a discharge nozzle.

Centrifugal pumps are often categorized according to the amount of fluid they move. The flow patterns are influenced by the design of the impeller and casing. The three main types of centrifugal pumps are single-stage, multistage, and vertical centrifugal. Each type of centrifugal pump has its own advantages. Most of them are highly efficient, have an incredibly wide capacity range, and require very little maintenance.

The main advantage of centrifugal pumps is that they are easy to maintain and cost less than other pumps. However, it is important to choose a pump that meets the needs of the application. For example, chemical-specific pumps are recommended for applications where hazardous chemicals are present.

Positive displacement pumps are a popular choice for some applications. They're particularly useful for handling high-viscosity fluids, moving liquids gently, and a range of other applications. Some are sealless and self-priming.

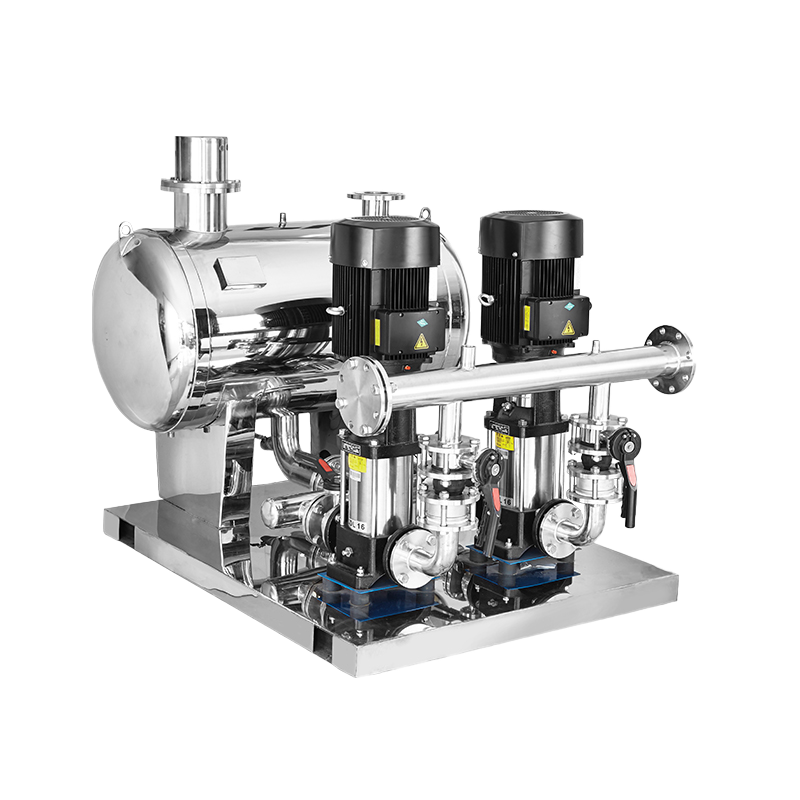

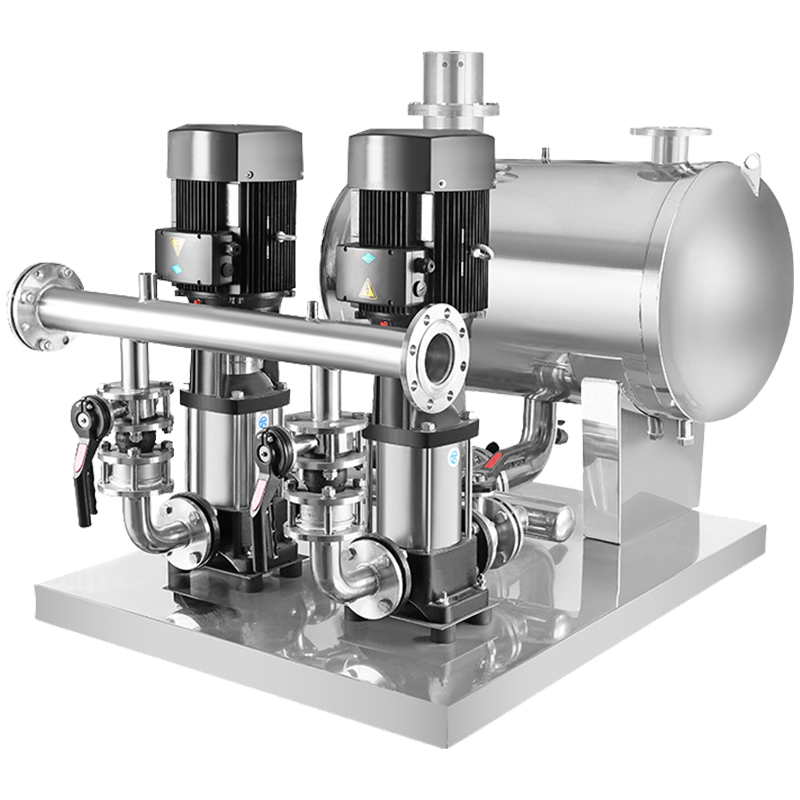

Stainless Steel centrifugal pump

Stainless Steel centrifugal pump

- DN Suction size: 50-100 mm (2"-4")

- DN Discharge size: 32-100 mm (1.5"-4")

- Flow Capacity Range: 0.6-240m3/h

- Head/Pressure Range: 22-66m

- Power Range: 1.1-37kw

- Stainless Steel centrifugal pump application- Water supply: filtration in water works, transportation and subarea water carriage, pressurization of main duct

- Industrial pressurization: flow wetting system, cleaning system

- Transportation of industrial liquid: water supply of boiler, condensed system, cooling and air conditioning system, machine tool support, light acid and alkali transportation

- Water treatment: distilled water system or separator, swimming pool, etc

- Farmland irrigation, medecine and sanitation, etc - Single impeller centrifugal pump made in stainless steel, making it the right pump for moving water and aggressive liquids in a vast number of applications where high chemical resistance is needed.

- Stainless steel single stage centrifugal centrifugal pumps are made with advanced techniques such as laser welding and hydroforming. Its characteristics are its impeccable appearance, a light and manageable structure, high efficiency in energy saving, long durability, corrosion-proof, silent, etc.

- Handling Clean Water,Chemically Non-Aggressive or Moderately,Aggressive Fluids,Water Supply,Pressure Boosting,Water Circulation,Irrigation Systems,Water Transfer for Green Houses.

English

English عربى

عربى

Fire Pump and System

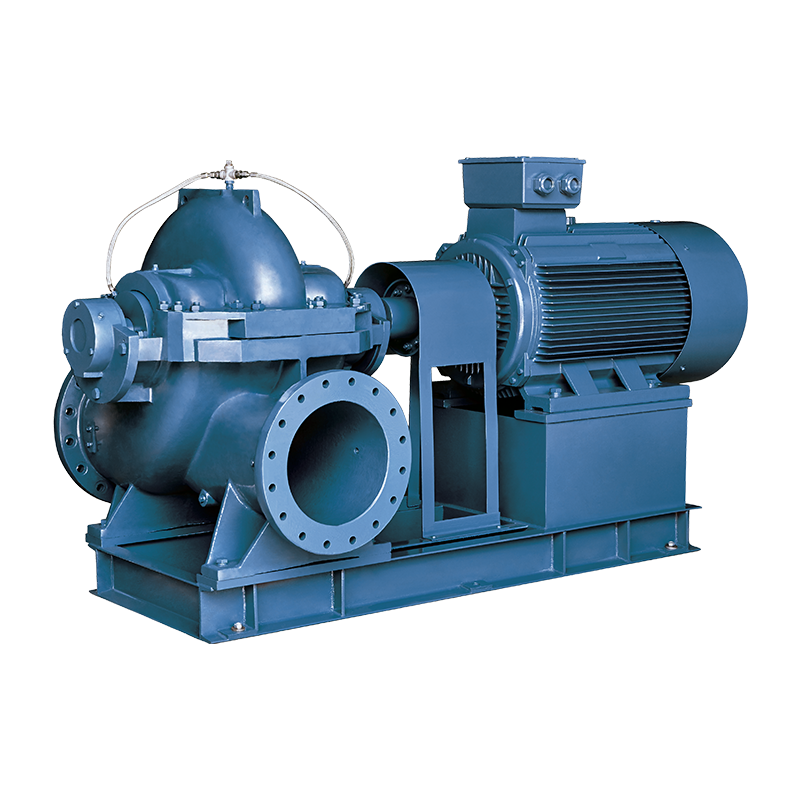

Fire Pump and System Split Case Pump

Split Case Pump Engine and Pump

Engine and Pump Long Shaft Pump

Long Shaft Pump Multistage pump

Multistage pump Water Supplier System

Water Supplier System Sewage Pump

Sewage Pump Industrial Pump

Industrial Pump Self-Priming Pump

Self-Priming Pump Inline Pump

Inline Pump Domestic Pump

Domestic Pump Electric Motor

Electric Motor Borehole Pump

Borehole Pump