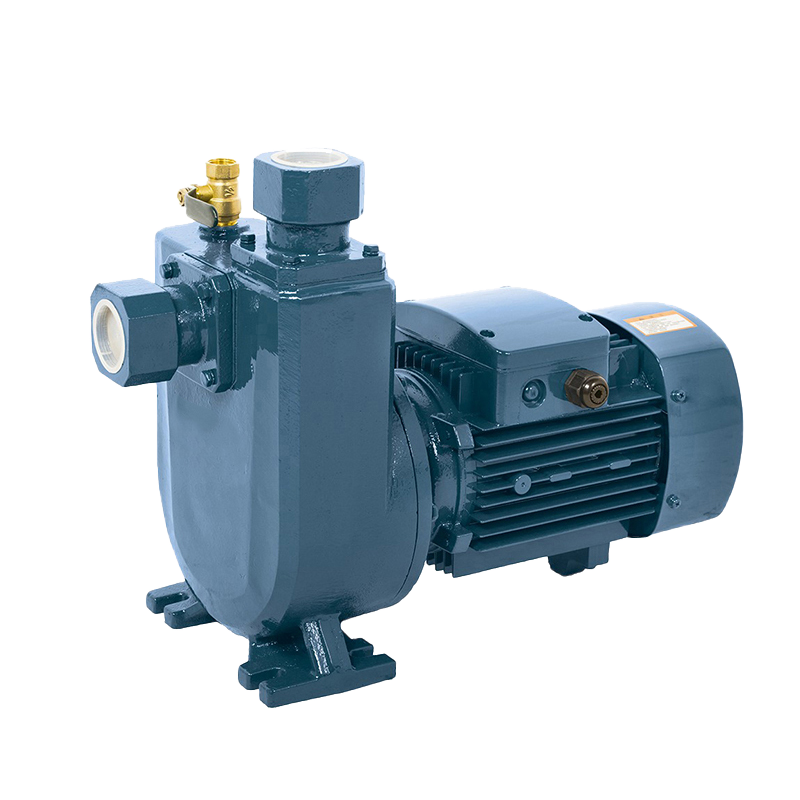

This article discusses the features of a Monoblock Centrifugal Water Pump and its operation. Generally, this type of pump has a wide range of performance and low operating costs. It is available in different designs, including those that are fitted with cast iron bodies and delivery ports and flanged suction. Other features of this type of pump include an integrated motor bracket and cast iron backplate. These pumps are mostly used for water supply.

The first and the foremost characteristic of a centrifugal pump is its ability to provide sufficient flow. This type of pump consists of an impeller that rotates around a central shaft, allowing the liquid or gas to be moved by the centrifugal force. As a result, they are suitable for many applications.

Monoblock pumps can be used in both domestic and industrial applications, as they are powered by a complete fenced induction motor. As a result, they have lower losses and are quiver-free. Furthermore, they are suitable for use in domestic applications, including agriculture and gardening. Other uses include industries with fresh water, power production factories, and hospitals.

This type of pump is perfect for pumping clean liquids, particularly those that are chemically nonaggressive. The pump's design also allows it to be installed in any position, with the inlet opening facing upwards. This type of pump is also suitable for general plant uses, including water supply, spray irrigation, and high pressure systems heating and conditioning. As such, it is suitable for all kinds of applications where clean liquids are required.

Monoblock Centrifugal Water Pumps are one of the most common types of pumps in India. They are designed to operate using centrifugal force, and are ideal for general plant and high pressure systems. They also have low noise levels and are compact and lightweight. They are comparatively easy to install.

Monoblock pumps are widely used in domestic, industrial, and agricultural applications. As their parts are located on a single shaft, they eliminate the losses caused by couplings and belt-driven sets. They are extremely efficient and scalable. They are available in a wide range of sizes, including 25x25x65x75x75.

Another feature of monoblock pumps is the fact that they are made with enhanced precision. In addition to this, they are designed to withstand voltage fluctuations of 180 to 250V. Monoblock pumps can also be used with liquids and gases. Some monoblock pumps can even be used with gas type boosters.

A Monoblock Centrifugal Water Pump's size is a factor that makes it ideal for rural areas. These pumps have great suction power, which makes them an ideal choice for shallow wells. They can reach eight meters of water, while their self-priming counterparts have a capacity of six meters.

Monoblock Close Coupled Centrifugal Water Pump

Monoblock Close Coupled Centrifugal Water Pump

- DN Range of Suction Pipe: 50-150 mm (2"-6")

- DN Range of Discharing Pipe: 32-125 mm (1.5"-5")

- Flow Capacity Range: 0-1750 GPM

- Head/Pressure Range: 1-15 Bar

- Power Range: 0.75-160Kw

- The industrial pump have two different pump head-smooth and rough, they are made of cast iron.The impeller is available in two materials-cast iron and stainless steel, for customers to choose.

- The centrifugal monoblock pump can be installed on a steel base or connected with the controller according to the customer's requirements. Additional piping, pressure tanks, valves and sensing lines can also be provided if required.

- The electric pump is coupled with YE3 high efficient motor with protection IP55 class F,and both square motor & round motor available, anti-corrosive coating pump case, quality NSK bearings, and wear resistance mechanical seal. Cast iron, brass and stainless steel impellers are all available.

- The pump could delivery water or liquid that physical and chemical similar to water.Liquid temperature shall not higher than 120 ºC.Ambient temperature is between-10°C and +50°C.The max. working pressure is 16 bar.

- The horizontal centrifugal pump is suitable for use with clean water and liquids that are not chemically aggressive towards the materials.The centrifugal pumps are recommended for use in water supply,cleaning sets, pressure boosting, firefighting sets, irrigation, industrial applications, water circulation in climatization sets, agricultural.

English

English عربى

عربى

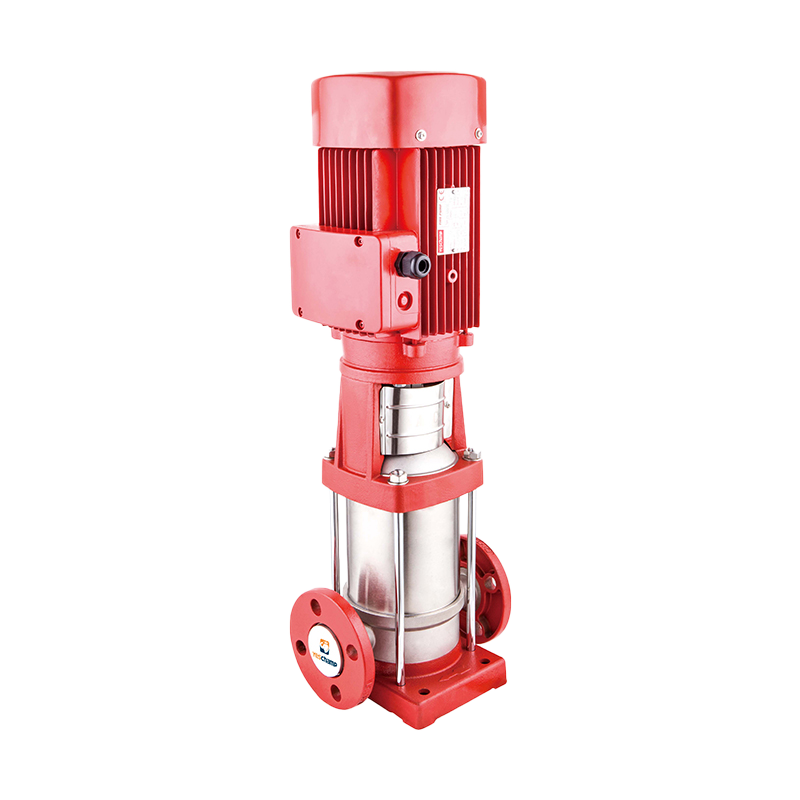

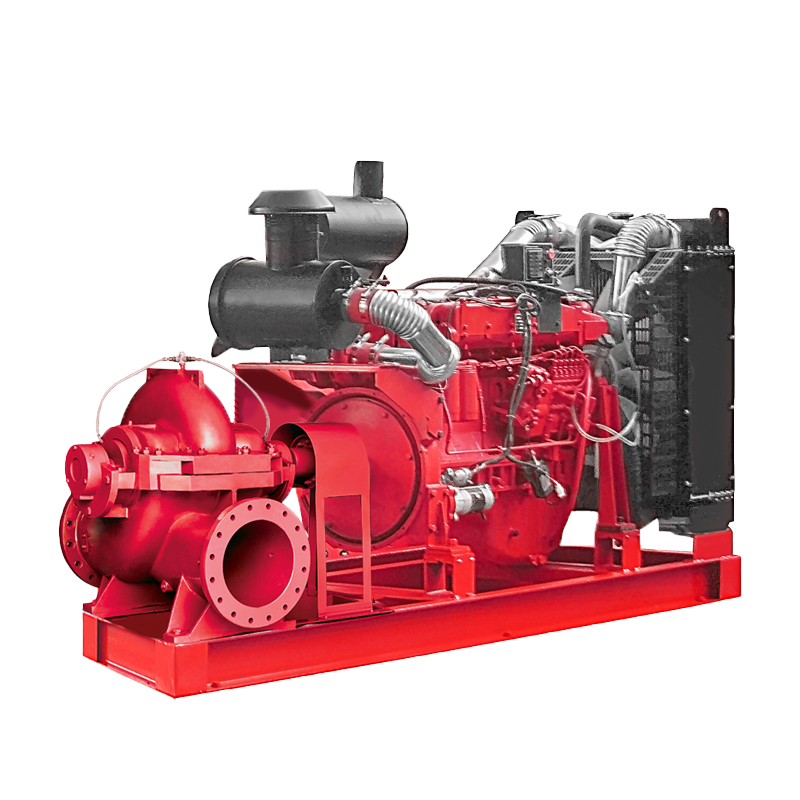

Fire Pump and System

Fire Pump and System Split Case Pump

Split Case Pump Engine and Pump

Engine and Pump Long Shaft Pump

Long Shaft Pump Multistage pump

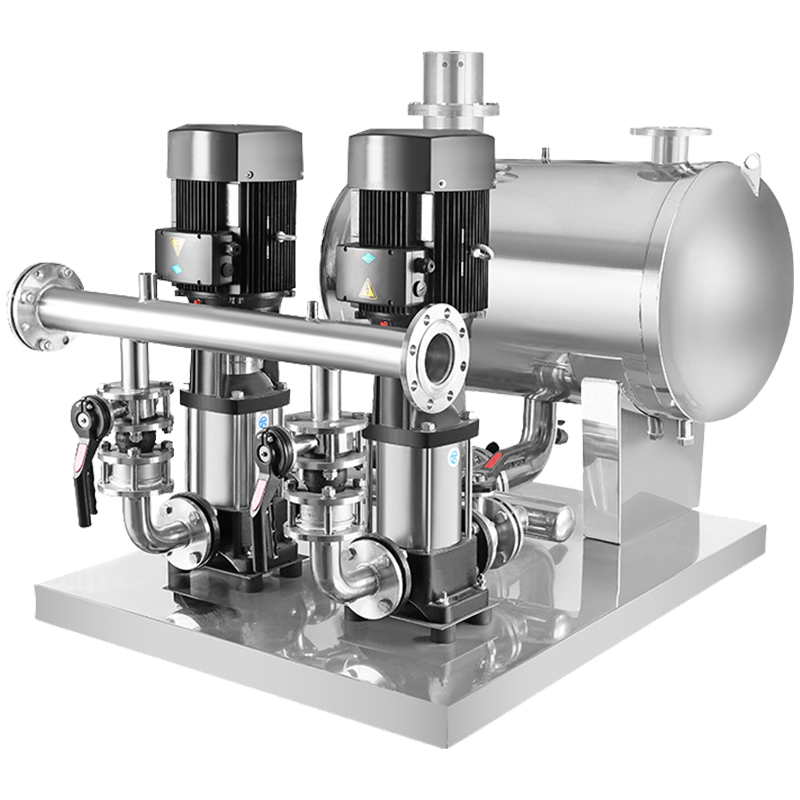

Multistage pump Water Supplier System

Water Supplier System Sewage Pump

Sewage Pump Industrial Pump

Industrial Pump Self-Priming Pump

Self-Priming Pump Inline Pump

Inline Pump Domestic Pump

Domestic Pump Electric Motor

Electric Motor Borehole Pump

Borehole Pump