Benefits of Industrial Water Pumps

When it comes to the efficiency of your industrial water pumping system, C&B Equipment has what you need. Their experienced team will provide you with affordable, reliable and sustainable solutions. The CR vertical inline multistage pump series is one example of a pump that meets a variety of specifications, including its energy efficiency and dependability. Additionally, these pumps are a breeze to use, and have features that ensure they are a cost-effective investment.

The first thing you need to know about pumps is that their performance curves are based on liquids that have a temperature of 65 to 85 degrees F. Water has a specific gravity of 1 Kg/dm3, so if your fluid is higher than this, you must make sure you adjust the pump accordingly. If you want to get the most out of your pump, consult with the factory to find out how different liquid temperatures will affect its performance. Remember that industrial pumps react differently in different environments, so it's important to know what you need before you purchase one.

There are many types of industrial water pumps on the market, each with a different purpose. Whether you need water for your manufacturing processes or to treat wastewater, these pumps are ideal. They are designed to meet your needs and are available in a variety of sizes, shapes and configurations. You can choose from a wide selection, so you can choose the best one for your needs. If you're unsure about which industrial water pump is right for you, consider consulting with a water pump guide.

In addition to high-end applications, industrial water pumps can help improve the flow efficiency of high-rise buildings. Pressure pumps are needed to pump supplies from wells and garden features. Other commercial uses of pumps include sewage treatment systems, boreholes, tanks and more. Choosing the right one is crucial for the efficiency of your industrial water pump, which should be installed by an expert. The benefits of industrial water pumps are many and they are well worth the cost.

While the performance of industrial water pumps is essential, they do not last forever. Proper maintenance will ensure the longevity of your equipment. The cost of repair and replacement can far outweigh the expense of the maintenance. For this reason, it is best to partner with a pump repair expert. They will institute a maintenance schedule, store parts and engineer perfect replicas for parts and extend the life of your industrial water pump. They will also save you time and money in the long run.

Centrifugal pumps are the most popular type of industrial water pump. They increase pressure by moving the fluid through a rotating impeller. They have many names, including concrete pumps, slurry pumps, paint pumps, and grinder pumps. Most pumps are designed for specific purposes and are classified according to how they move water. Positive displacement pumps and centrifugal pumps are best suited for continuous transfer of water. They are also available in a wide range of configurations.

English

English عربى

عربى

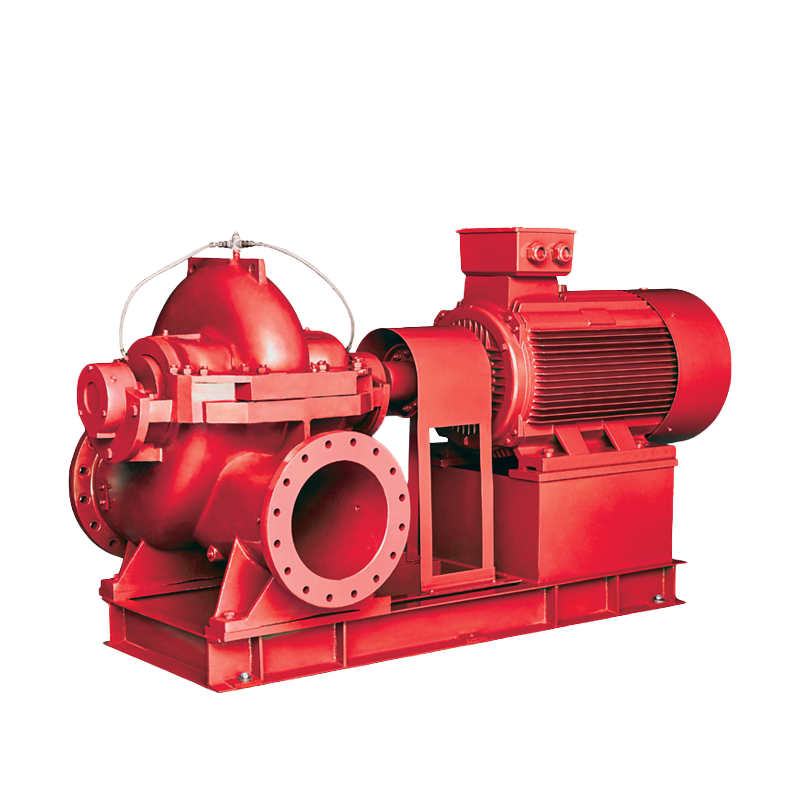

Fire Pump and System

Fire Pump and System Split Case Pump

Split Case Pump Engine and Pump

Engine and Pump Long Shaft Pump

Long Shaft Pump Multistage pump

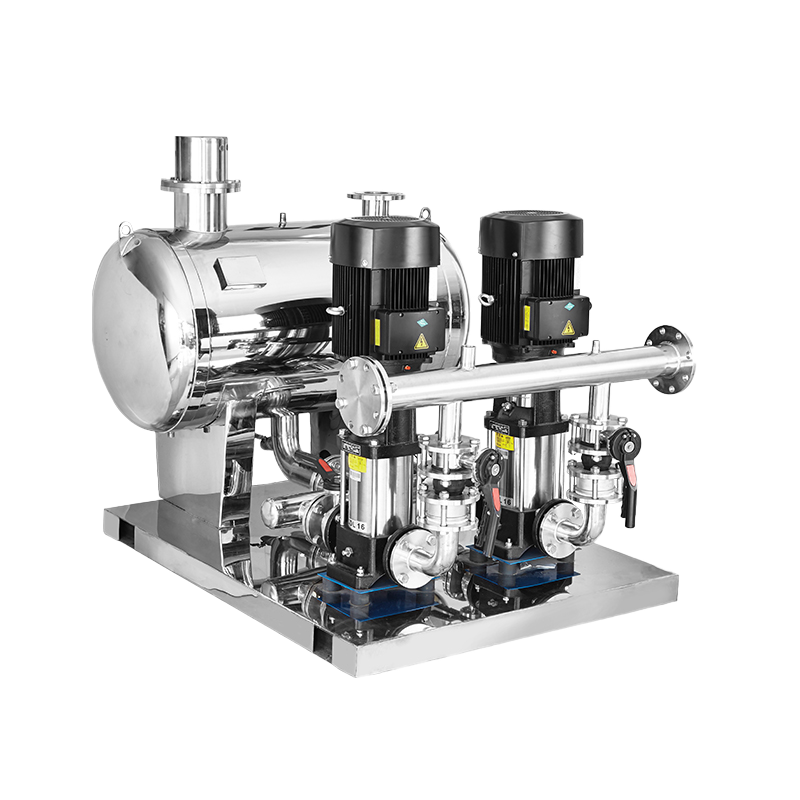

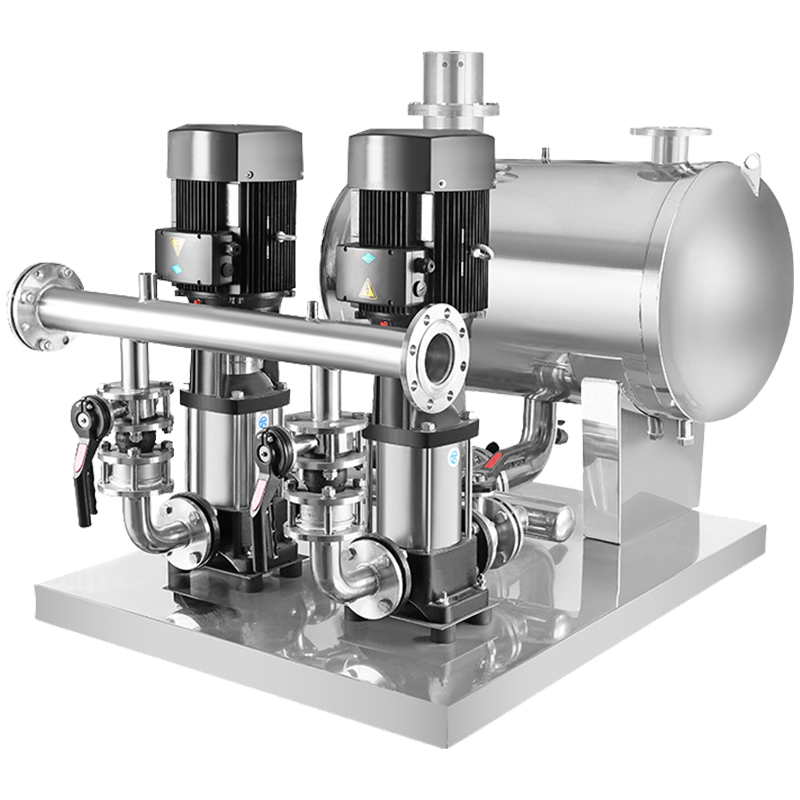

Multistage pump Water Supplier System

Water Supplier System Sewage Pump

Sewage Pump Industrial Pump

Industrial Pump Self-Priming Pump

Self-Priming Pump Inline Pump

Inline Pump Domestic Pump

Domestic Pump Electric Motor

Electric Motor Borehole Pump

Borehole Pump